The selection of cold storage panels

With the development of industry and the improvement of people's living standards, preservation and freezing have become an important part of the market. As an important component of the cold storage building, the selection of cold storage panels is very important for the daily operation of the cold storage. Cold storage has relatively high requirements for air temperature, humidity, and environment. Choosing the right panels can not only maintain the cold storage efficiency, but also save energy and reduce costs.

The selection of cold storage insulation materials are important impact on the energy efficiency and operating costs of the cold storage. The following are some common cold storage insulation materials:

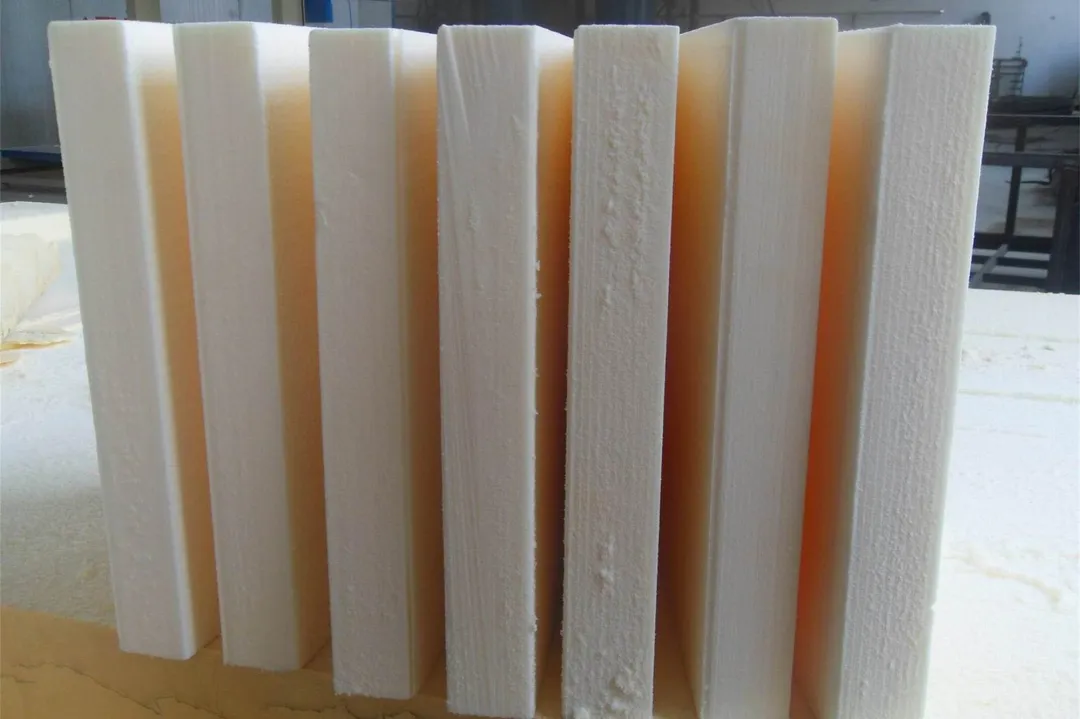

Polyurethane (PIR): Polyurethane is a commonly used cold storage insulation material with excellent thermal insulation properties and good mechanical strength. It can effectively prevent heat transfer and reduce cooling loss. Polyurethane insulation material is also moisture-proof, waterproof and corrosion-resistant, and is suitable for various cold storage environments.

Extruded polystyrene (XPS): XPS is a high-performance thermal insulation material with low thermal conductivity and good compressive strength. It is often used in cold storages with high thermal insulation requirements.

Rock wool: Rock wool is a fiber made from melted rock. It has good thermal insulation and sound absorption properties and excellent fire resistance. And extra protection is needed during construction.

Phenolic: It is foamed from thermosetting phenolic resin. It has good corrosion resistance and thermal insulation effect, strong fire resistance, does not burn when exposed to open flames, has low smoke, non-toxicity, and no dripping.

In the cold storage industry, polyurethane has great advantages due to its excellent thermal insulation performance, excellent moisture-proof and waterproof performance, excellent fire resistance and high temperature resistance, and good construction performance. It has become an ideal choice for cold storage insulation materials and can ensure the safety of cold storage. , operate efficiently while meeting environmental protection requirements.

WISKIND’s COLORSPAR® Polyurethane Cold Storage Panel is jointly developed with International Chemical BASF. Its core material is BASF's pentane-foamed Elastopir® rigid foam. It can pass the requirements of GB8624-2012 B1 level and meet the market's demand for high flame retardant products. needs. Moreover, Elastopir® material has a lower thermal conductivity, and its thermal insulation performance can be improved by 20% compared with traditional insulation materials. It is the best material for building various cold storage projects and can help achieve a more energy-saving and sustainable future.

Please read on, stay posted, subscribe, and we welcome you to tell us what you think.

online service

online service +86-0543-2165081

+86-0543-2165081 market@wiskind.com

market@wiskind.com +8613754666378

+8613754666378 wiskindbob

wiskindbob