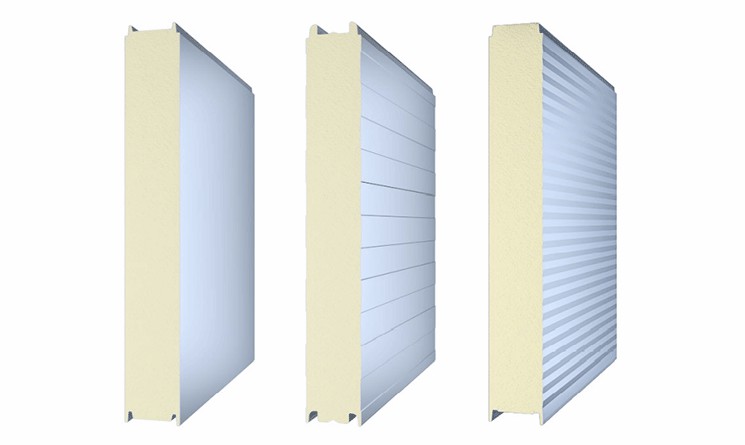

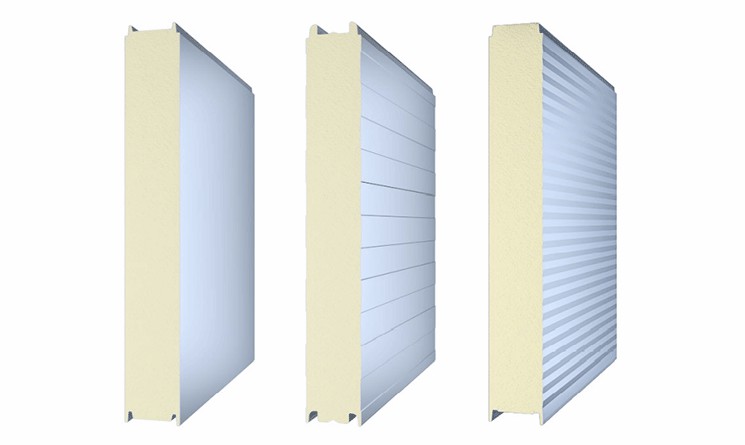

Steel Sandwich Panel, as a new building material, is a self-supporting composite board composed of bimetallic surface and insulating core material bonded between two metal surfaces. Set fire prevention, heat preservation, waterproof, weather resistance, wind resistance, pressure resistance, sound absorption, sound insulation in one, in recent years, widely used in all kinds of industrial buildings. Sandwich board is composed of surface material and core material, this paper from these two aspects to explain the sandwich board quality classification.

Color coated sandwich board surface material

1. The steel plate

Color coated steel plate is made of cold rolled steel plate, electric galvanized steel plate, hot galvanized steel plate or aluminum zinc plate as the base plate, after degreasing, phosphating, chromated treatment, continuous roll coating of organic coating, and baking. The whole process through a series of production management, quality control. Color coating steel plate commonly used coatings are PVDF polyvinylidene fluoride, HDP high weather resistant polyester, PE polyester coating.

2. Aluminum plate

Excellent corrosion resistance can improve the overall durability of the building, and the life cycle of the building. With good flexibility and processing performance, paint surface is not explosive edge, can be processed into plane, arc surface and other complex set shape, light weight but high strength, has higher recycling value.

Color coated sandwich board core material

1. Rock wool/glass wool

Rock wool sandwich board is a kind of basalt as raw material made of sandwich board. With excellent fire performance, good sound insulation and heat insulation, and sustainable recycling. Non-combustible glass wool, light weight, low thermal conductivity, good sound absorption, good waterproof performance, corrosion resistance, good chemical stability, good processing performance, has good economic applicability.

2. Polyurethane PIR/PUR

Rigid polyurethane has the characteristics of moisture-proof, waterproof, fireproof, flame retardant, high temperature resistance, frost resistance and sound absorption. With ultra-high temperature stability and fire rating, no freon discharge, energy saving and environmental protection, can be widely used in industrial building cold storage projects.

According to different project nature, can choose different sandwich plate quality. And the sandwich board has obvious advantages in the aspects of rapid installation and use, in the aspects of assembly and disassembly, and the turnover and reuse index of materials, which are indispensable new lightweight building materials.

online service

online service +86-153 1435 3017

+86-153 1435 3017 market@wiskind.com

market@wiskind.com +86-153 1435 3017

+86-153 1435 3017