Project Name: Xingtai Wanda Tire Factory

Application system:Insulation Curtain Wall Panel

If materials become the shackles of architects, modern architecture will be much bleak.

If the designer's creativity cannot be restored perfectly, the history of mankind will be diminished.

The best materials can promote unconstrained creativity,

The best craftsmanship can realize the ultimate landing of creativity,

Materials and craftsmanship combine technique, structure and aesthetics.

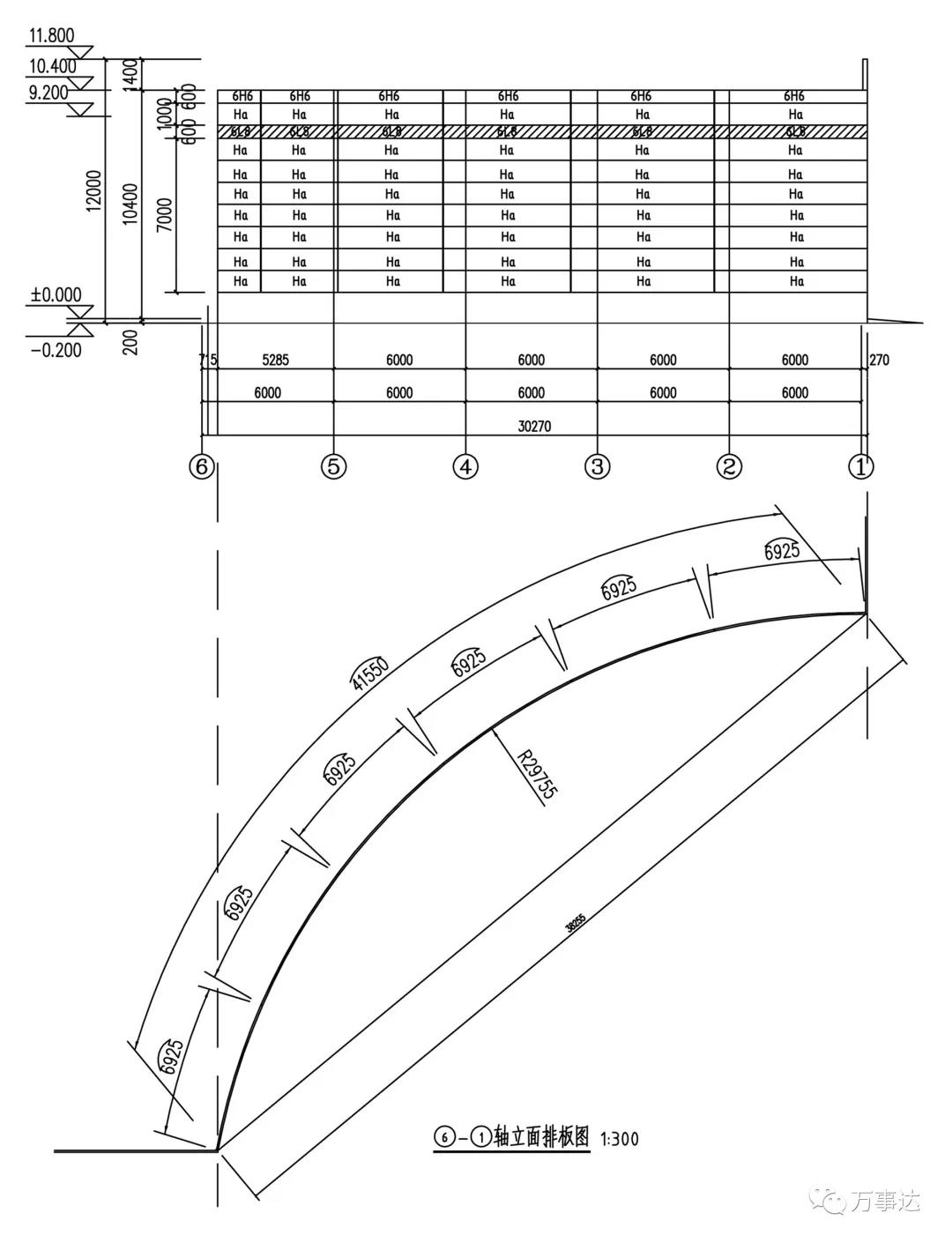

In modern buildings, metal thermal insulation curtain walls have become a major trend, but due to the limitations of equipment and technology and other factors, curved thermal insulation curtain walls are relatively rare. In August 2018, relying on bold innovation and exquisite craftsmanship, Shandong Wanshida Construction Steel Products Co., Ltd. creatively completed the design, production and installation of the curved color diamond metal curtain wall in the Xingtai Wanda tire project. With a span of 41.5 meters, a total height of 11.8 meters, and an arc of 1.4, the large curved wall with fancy colored diamonds contributes a graceful "willow waist figure" to the project.

The arc shape is ingenious

Without being restricted by materials, designers can pursue architectural visual effects. In the second phase of the Wanda Tire Factory in Guangzong County, Hebei Province, in order to fit the circular pond landscape in the park, one corner of the building was designed as a huge curved wall.

Since the current domestic and international first-line metal insulation board equipment basically belongs to the production process of flat panels, the production and installation of curved panels has become a technical problem in the design of the layout and the accuracy of manual manufacturing. In particular, the single board is 6.9 meters long, has a total span of 41.5 meters, and an arc of 1.4.

How to go from straight panel to arc panel? This is not only a test of the quality of the board, but also a test of the tacit understanding of manual skills and mechanical operation.

"The most difficult thing is not to make an arc, but how to ensure a smooth appearance and regular interior."

Project technical plan designer Yang Haitao said, “We designed the arc bed, cut the seams from the back, and then fixed it on the arc bed. The key is how to fix it and achieve seamless treatment on the back. The back side is cut and seamed, generally Fixed with angle steel, but the cut marks on the back are exposed, which is very unsightly from the back, and the angle steel is particularly troublesome for installation. After research and testing, we finally selected galvanized steel tape to shape the curved plate. The width of the plate is 1000 and 1.5 A thick galvanized steel strip with a width of 200 is fixed on the back of the plate in two upper and lower sections to shape the bending arc. The toughness and hardness of this galvanized steel strip are just right. The steel strip is nailed with fancy styles to ensure the maximum thickness The bonding strength reduces the deformation of the plate. In addition, we chose 880 profiled steel plate with a smaller wave crest to be attached to the back of the plate to ensure the beauty of the back of the curved plate and the operability of subsequent smooth installation. The ready-made materials also save the overall cost, which can be described as multi-tasking."

Fineness interpretation ingenuity

Fine design is the first step. What is more difficult is that a considerable part of the whole process depends on manual skills. From curved beds, sheet cutting, fixing galvanized steel strips, etc., many production details reflect the ingenuity of Wiskind.

"In the production, we aim for zero error." Ma Rufei, manager of the Envelope Intelligent Manufacturing Division, said, "The cutting of the backplane is very difficult, especially the cutting depth. The shallow arc is not enough, and the deep affects the overall strength of the plate. Very difficult. Take it. According to the radian, the length of the plate, the thickness of the plate, after careful and detailed calculation, we have come up with an accurate value. In the actual scribing and cutting, it is also full of challenges. This requires too much precision for the worker's processing It can only be done slowly and carefully."

It is estimated that 20 knives per meter and the same depth of each knife are undoubtedly a difficult task for workers. Crafted by hand, each knife reflects the outstanding craftsman spirit of Wiskind.

Wang Yuqiang, the sales representative of Wiskind Beijing Division, who participated in the installation and construction, said, “During the on-site installation process, the bending accuracy of the purlin completely reached the designed arc. After the arc slab arrives, the vertical purlin is installed to fully fit the arc slab. The arc-shaped galvanized steel strip on the back is very convenient for installation, and its stabilization effect is also very prominent."

Cut so many knives per meter, will it affect the toughness and heat preservation effect of the board? "Of course it will be affected. However, considering the bonding properties of the plate itself, the plasticity of the steel plate and the processing accuracy of the workers, we have reached the conclusion that it fully meets the requirements of parameters such as thermal insulation effect, flatness, and service life. . The result proves that we have made products that satisfy our customers.” said Wang Yuqiang, the sales representative of Wiskind Beijing Division.

40 years of innovation

"The curved insulation board metal curtain wall is very rare. It brings vitality and dynamics to the building, and also reflects our strength and high level of service. In the future, we will be able to design and design curved curtain walls faster and better. Construction gives the space creativity and inspiration, and better serves customers.” said designer Yang Haitao.

As a brand supplier and service provider in the construction steel industry, Wiskind has accumulated rich professional experience and innovation capabilities for 40 years, from materials to construction, to provide architects with perfect and personalized solutions.

Wiskind independently researches and develops rock wool/glass wool + polyurethane side-sealed sandwich panel products, which integrates heat preservation and fire protection functions. It has introduced two European advanced Italian PUMA and OMS production lines and technical processes, online high-pressure foaming, and ultra-long double-track molding. , To realize the professional and large-scale production of polyurethane panels.

The water-repellent rock wool has a heat resistance range of -60℃~+500℃, and a fire rating of A grade. The color coated steel plates are purchased from Shanghai Baosteel, BlueScope, Yehui, United Steel, Maanshan Iron and Steel and other well-known companies, with complete product colors and specifications. Its special high-quality color-coated board can be used for decades in high temperature, high humidity and acid-base corrosion environment.

Cut so many knives per meter, will it affect the toughness and heat preservation effect of the board? "Of course it will be affected. However, considering the bonding properties of the plate itself, the plasticity of the steel plate and the processing accuracy of the workers, we have reached the conclusion that it fully meets the requirements of parameters such as thermal insulation effect, flatness, and service life. . The result proves that we have made products that satisfy our customers.” said Wang Yuqiang, the sales representative of Wiskind Beijing Division.

40 years of innovation

"The curved insulation board metal curtain wall is very rare. It brings vitality and dynamics to the building, and also reflects our strength and high level of service. In the future, we will be able to design and design curved curtain walls faster and better. Construction gives the space creativity and inspiration, and better serves customers.” said designer Yang Haitao.

As a brand supplier and service provider in the construction steel industry, Wiskind has accumulated rich professional experience and innovation capabilities for 40 years, from materials to construction, to provide architects with perfect and personalized solutions.

Wiskind independently researches and develops rock wool/glass wool + polyurethane side-sealed sandwich panel products, which integrates heat preservation and fire protection functions. It has introduced two European advanced Italian PUMA and OMS production lines and technical processes, online high-pressure foaming, and ultra-long double-track molding. , To realize the professional and large-scale production of polyurethane panels.

The water-repellent rock wool has a heat resistance range of -60℃~+500℃, and a fire rating of A grade. The color coated steel plates are purchased from Shanghai Baosteel, BlueScope, Yehui, United Steel, Maanshan Iron and Steel and other well-known companies, with complete product colors and specifications. Its special high-quality color-coated board can be used for decades in high temperature, high humidity and acid-base corrosion environment.

Cut so many knives per meter, will it affect the toughness and heat preservation effect of the board? "Of course it will be affected. However, considering the bonding properties of the plate itself, the plasticity of the steel plate and the processing accuracy of the workers, we have reached the conclusion that it fully meets the requirements of parameters such as thermal insulation effect, flatness, and service life. . The result proves that we have made products that satisfy our customers.” said Wang Yuqiang, the sales representative of Wiskind Beijing Division.

40 years of innovation

"The curved insulation board metal curtain wall is very rare. It brings vitality and dynamics to the building, and also reflects our strength and high level of service. In the future, we will be able to design and design curved curtain walls faster and better. Construction gives the space creativity and inspiration, and better serves customers.” said designer Yang Haitao.

As a brand supplier and service provider in the construction steel industry, Wiskind has accumulated rich professional experience and innovation capabilities for 40 years, from materials to construction, to provide architects with perfect and personalized solutions.

Wiskind independently researches and develops rock wool/glass wool + polyurethane side-sealed sandwich panel products, which integrates heat preservation and fire protection functions. It has introduced two European advanced Italian PUMA and OMS production lines and technical processes, online high-pressure foaming, and ultra-long double-track molding. , To realize the professional and large-scale production of polyurethane panels.

The water-repellent rock wool has a heat resistance range of -60℃~+500℃, and a fire rating of A grade. The color coated steel plates are purchased from Shanghai Baosteel, BlueScope, Yehui, United Steel, Maanshan Iron and Steel and other well-known companies, with complete product colors and specifications. Its special high-quality color-coated board can be used for decades in high temperature, high humidity and acid-base corrosion environment.

Excellent production technology, excellent product specifications, and exquisite manual skills are all guarantees for the perfect presentation of the curved metal curtain wall. Innovation has become the corporate gene of Wiskind for 40 years of development.

Please read on, stay posted, subscribe, and we welcome you to tell us what you think.

online service

online service +86-153 1435 3017

+86-153 1435 3017 market@wiskind.com

market@wiskind.com +86-153 1435 3017

+86-153 1435 3017