As the seasons change and the time of harvest approaches once again, ensuring the safe storage and freshness of food has become an important task that we cannot afford to ignore. 1. Professionalism to help the project reach the full force Hubei is located in a medium-temperature, high humidity grain storage area. Every year during the wheat harvesting season, the middle and lower reaches of the Yangtze River are in the rainy season, and the temperature of the grain silo rises quickly. High temperature not only affects the quality of grain, but also leads to the proliferation of pests. High-quality grain storage and logistics facilities are the foundation and key to guaranteeing food security. The National Grain Modern Logistics and National Rice Trading Centre Frozen Products Processing Phase I Project is a national key project approved by the State Grain Administration and projected by the National Development and Reform Commission. The project is situated on the beautiful Yangtze River, which opens up the ‘artery’ of waterway transport. The project is located on the left bank of Yangluo Waterway, Longkou Road, Shuangliu Street, Xinzhou District, Wuhan City, adjacent to the Yangtze River in the west, with a total construction area of about 117,000 square metres, including frozen product processing plant, centralised equipment rooms and outdoor supporting frost water pools. As a professional supplier of assembled cold storage enclosure system, Wiskind, with high-quality products and services, has contributed to the success of the project. 2.High quality to build a fortress for food security Good products create good food storage conditions. Wiskind Ricochet® polyurethane cold storage panels were used in the frozen materials cold storage units of the project, totalling about 17,000m2. Ricochet® polyurethane cold storage panels adopt a new generation of polyurethane rigid core material, with dense foam and surface material fully bonded to form an uninterrupted heat shield, effectively blocking heat conduction, with excellent heat preservation performance, and effectively guaranteeing the quality of grain. The core material of the cold storage board is thermosetting material, which has no melting and dripping in case of fire and heat, and has good structural stability, which meets the customer's demand for higher fireproof performance. Polyurethane composite with metal surface material improves the flame retardant property of the board; at the same time, the closure rate of polyurethane rigid foam thermal insulation material can reach more than 95%, and the excellent fire-retardant, flame-retardant and waterproof performance of Wiskelite Colour Crystal® creates a safe and durable cold storage fortress for grain storage. Grain is stored in the ground, and grain is stored in technology. The project contains two three-dimensional cold storage units, with a net height of 20.1m and 0.45m into the ground, which is a bit higher comp...

On September 6, Typhoon "Yagi", the strongest autumn typhoon to land on the Chinese mainland since the founding of New China, hit Hainan with a strength of 17, causing 526,100 people in Hainan province and direct economic losses of more than 80 billion yuan. Only ten days later, Typhoon Bebinca made landfall in Lingang New City, Pudong, Shanghai, with a maximum wind strength of 14 near the center, becoming the strongest typhoon to make landfall in Shanghai in 75 years, and continued to exert enormous wind and precipitation intensity on the eastern coastal areas, resulting in widespread infrastructure damage and social impact. In particular, the peripheral protection system of industrial buildings, in the case of extremely high wind speed, often become the most vulnerable part, which has a huge impact on projects under construction. Faced with the test of two successive “epic” typhoons, the Shanghai project and a food industry project in Hainan built by Wiskind were safe after the storm, and the customer specially sent a letter of praise to Wiskind’s construction quality and the excellent wind resistance performance of the product. (shooting on spot in the process of construction) The weather forecast shows that the 13th typhoon "Bebinca" will land in Shanghai Pudong Lingang New City around 7:30 on September 16, Pudong launched a level I response action to protect people's lives and property safety. At the same time, the project under construction by Wiskind is also undergoing intense inspection and preparation before the typhoon. First of all, in the further design phase of the project, Wiskind carried out the wind resistance design combining the structure and the envelope system according to the load specification requirements (the design wind load in Shanghai is equivalent to a class 12 typhoon); Before the storm, according to the typhoon level warning, we reviewed again to determine that the project envelope structure system has the ultimate ability to resist the strong typhoon of category 14 beyond the design. Secondly, all key areas that may be affected by the typhoon were investigated. Then check the connection joints of bolts and purlins of all unfinished works to ensure that they are tight; At the same time, clean up the site in time, arrange and temporarily fix the temporarily stacked materials. After the typhoon, the project manager of Wiskind, who was required to withdraw, rushed to the project site as soon as possible. Thanks to Wiskind’s excellent product performance and wind resistance design, excellent construction quality and emergency protection measures before typhoons, the enclosure system is intact and not damaged by typhoons. Wiskind’s continuous research and development and progress in the metal enclosure system, through the verification of this typhoon, to maintain the safety of the customer's industrial property, which has been highly recognized by the project party. O...

On August 20, China's first 3A game "Black Myth: Wukong" was launched. And as of September 4, the sales volume of the whole platform may reach 17.8 million copies, with a total revenue of about 6 billion yuan. The success of the game, which reinvigorates the "Journey to the West" genre in the new generation, is not only a commercial achievement, but also an important milestone in the development of China's game industry. In addition to the carnival caused by the game itself, the Chinese aesthetic is amazing, such as the mountain path lying stone, winding path to quiet and peaceful place...... From the ruins of the ancient temple to the magnificent palace buildings, those historical ancient buildings, sculptures, murals and other actual shooting places are suddenly "exploded", and many scenes in the game are highly restored through real three-dimensional reconstruction technology. According to incomplete statistics, the game location covers 36 scenic spots across the country. For more than 40 years, Wiskind, as the industry's leading supplier of building envelope and building steel structure products, provides products and services for 54 countries and regions around the world, which is committed to providing customers with professional and careful engineering services. Today, let me lead you to follow the shooting footsteps of "Black Myth: Wukong" and enjoy the excellent projects of Wiskind across the country. "Black Myth: Wukong" selected 36 scenic spots as game scenes across the country, of which Shanxi, known as the "paradise of ancient architecture lovers", has 27 locations, such as Small West Heaven, Jade Emperor Temple, Iron Buddha Temple and so on. In reality, Shanxi's location has also caught this wave of "splashy flow" and has become a new hot spot in the tourism circle. The tomb of Lingyan Temple and the Four Gate Pagoda in Jinan, Shandong Province were also included in the game as shooting locations. Lingyan Temple is located in Wande Town, Changqing District, Jinan City. It ranks first among the four famous temples in the world, along with Guoqing Temple in Zhejiang Province, Qixia Temple in Nanjing and Yuquan Temple in Hubei Province. Monk Xuanzang once lived in the temple to translate scriptures. In addition, the Four Men Tower is the only existing Sui Dynasty stone pagoda in China, and is also the earliest and most complete preserved single-storey pavilion pagoda in China. The scenic spot is nicknamed "Cat Temple" by netizens because of the large number of cats. Located in Lantian, Shaanxi Province, the Shuilu Temple is known as "the first three-dimensional interlocking wall sculpture in the world". The walls and columns are inlaid with more than 3,700 statues, including not only figures, but also pavilions, flowers, birds, insects, fish, exotic animals, and so on. It is famous for preserving the exquisite and rare colored sculptures in ancient times. Dule Temple, located in Tianjin, was bui...

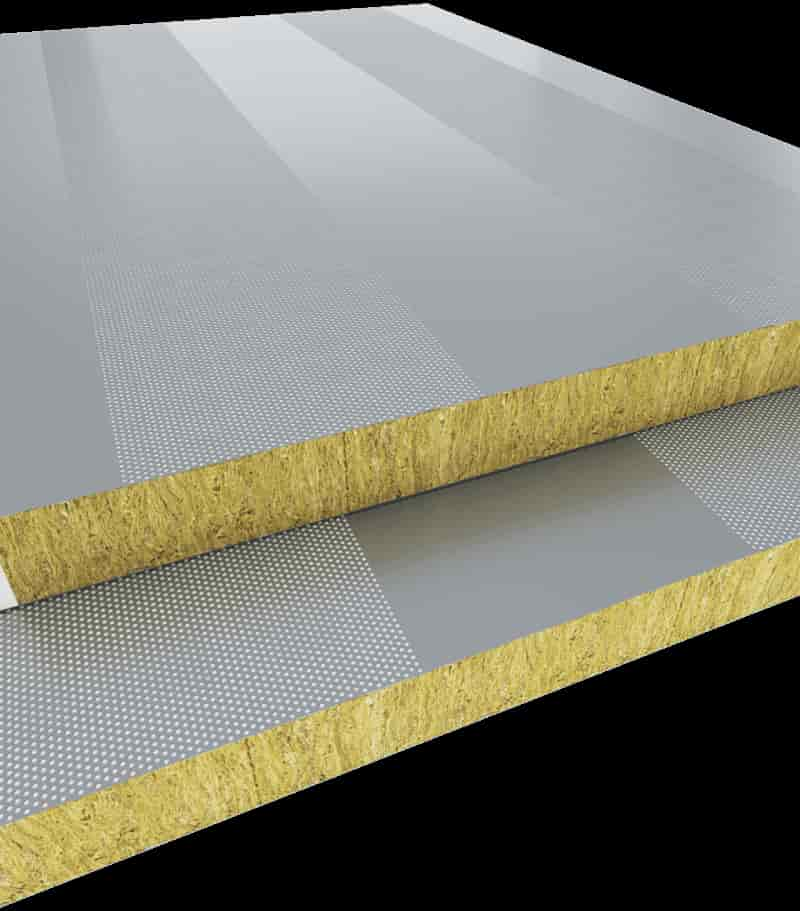

Cold chain logistics, as an important link to maintain the freshness of food and ensure the safety of medicines and other materials, plays an indispensable role in the modern supply chain and logistics system. With the strong support of China's policies, cold chain logistics is developing healthily and orderly. For the refrigeration facilities, we use the Colorspar® polyurethane cold storage panel jointly developed by Wiskind and international chemical giant BASF. This product has excellent thermal insulation performance. The rigid core material with polyurethane pentane B1 foaming technology is fully bonded to the surface material to form uninterrupted thermal shielding, effectively blocking the heat conduction, and is suitable for the working temperature of -170 ° C ~+150 ° C. Excellent thermal insulation performance, can effectively reduce building energy consumption, improve energy efficiency. The hard core material of the product is thermosetting material, no melting and dripping in the event of fire and heat, good structural stability, with excellent high and low temperature stability, reaching the national B1 level safety fire prevention regulations, and the cold storage board uses high-quality color coated steel plate or stainless steel plate surface material, which improves the flame retardant performance of the plate, excellent corrosion resistance, and further extends the service life of the building. Create safe and durable industrial buildings and cold warehouses for customers. The project belongs to the elevated storage, and the height of the cold storage is more than 8 meters. Wiskind Cold Chain production line introduces OMS advanced equipment and technology, and the production line is 320 meters long, which can produce a maximum board length of 24 meters, to meet the needs of the project. The cold storage board is prefabricated in the factory and assembled on site, which is more simple and fast, greatly shortens the construction period, reduces the construction labor cost and material loss. According to the practical application of the project, a scientific and reasonable cold storage design scheme is developed for customers, and the special board of Wiskind cold storage fire partition is adopted to fully consider the safety of cold storage. The core material of the product is selected as high-quality 98% hydrophobic rock wool, excellent fire retardant performance, and the fire rating reaches Class A. At the same time, in order to ensure the efficient operation of the cold storage, the project uses different types of cold storage thermal insulation doors to increase the thermal insulation measures of the cold storage. As a professional supplier of prefabricated cold storage enclosure system, in the future, Wiskind will be committed to continuous innovation, ingenuity to create green, low-carbon and comprehensive cold storage solutions, injecting professional momentum and exc...

Industrial noise has a great impact on people and equipment. Long-term exposure to high noise environment will do great harm to the health of employees. Constant interference from noise can also lead to distraction and decreased productivity, increasing the risk of errors and accidents at work. In terms of equipment, high noise environments can lead to increased wear and tear of mechanical components, thereby increasing the risk of equipment failure, shortening the service life of equipment, and increasing maintenance and repair costs. Then, the use of noise-reducing wall and roof enclosure materials in the factory construction stage has obvious cost advantages, reducing subsequent maintenance and renovation costs. As a leading supplier of building metal envelope systems, Wiskind has developed the innovative Acous® sound absorbing sandwich panel for industrial noise, which has outstanding performance in noise reduction and is the preferred material to solve the problem of factory noise. Acous® sound insulation sandwich board design can achieve indoor noise reduction of about 60%, sound insulation increase by 100%, through the non-punching area, rock wool, punching area combination, to achieve low, medium and high frequency balanced absorption, and it also has good corrosion resistance and mechanical properties. When it is used as a building roof system, in addition to significantly reducing workshop noise, it has both roof waterproof and thermal insulation functions, becoming the best solution for noise reduction in industrial buildings. In addition, the simple and efficient installation process of Wiskind Sound Acous® acoustic insulation sandwich panels can quickly improve the sound insulation performance of buildings, optimize the working environment of employees, and reduce the health and safety risks caused by noise.

On August 3, Liu Zhiteng, deputy general manager of Shandong Company of China Inspection and Certification Group, and AshuraKilewela, director of Tanzania Bureau of Standards, led a delegation to visit Boxing Economic Development Zone. Wang Hui, Secretary of the Party Group and director of Binzhou Investment Promotion Center, Fan Guolong, Standing Committee member and deputy county Governor of Boxing County Committee, Liu Zhaoqiang, member of the Party Working Committee and deputy director of the Management Committee of Boxing Economic Development Zone accompanied the inspection activities. The delegation visited Wiskind Construction Steel Co., LTD., and learned about the company's development history, research and development and product quality control in detail. The delegation said that Chinese manufacturing is very competitive in the global market, and the management of sheet metal enterprises in the economic development zone is standardized and the product quality control is strict. It is hoped that in the future trade between China and Tanzania, more and more sheet metal products will be exported to Tanzania and promote the economic and trade cooperation between China and Tanzania. Wiskind insists on becoming a respected enterprise capable of sustainable development, and our products have also got FM and CE certifications. Wiskind has been strictly controlled in product research and development, quality control and after-sales service, helping to promote China-Tanzania economic and trade cooperation.

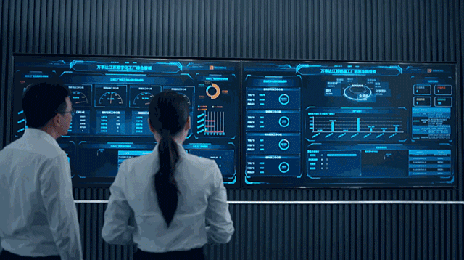

The third plenary session of the 20th Central Committee of the Communist Party of China (CPC) was recently held in Beijing. The NPC deliberated and adopted the Decision of the CPC Central Committee on Further Comprehensively Deepening Reform and Promoting Chinese-Style Modernization. The first mention of the term “digital intelligence” in the “Decision” reflects that the integrated development of “digitalization + intelligence” has become the latest engine for the development of new quality productivity. As the industry's leading supplier of building envelope and building steel structure products, Wiskind has never stopped the pace of digital construction in recent years. In the field of intelligent manufacturing, advanced equipment, technology and information technology are deeply integrated, running through the whole process of product delivery from design, production, storage and transportation to service. The digital transformation of business operations and factory production puts data at the heart of decision making. Wiskind is constantly optimizing and upgrading its digital infrastructure, and through its customer management system, so that we can better understand and respond to customer needs, achieving customized services and precise marketing strategies. On the design side, Wiskind uses the innovative digital intelligent design platform to realize the automatic operation of a series of processes from standard database to intelligent design, automatic drawing, data cloud storage, and also supports the online operation of the whole process of budget and detail design. Moreover, this platform makes the design work efficient and intelligent, and strengthens the reliability and timeliness of delivery to customers. On the production side, Wiskind uses the four information systems of MES, WMS, MMS and SCADA to meet the digital needs of the manufacturing side in all aspects of manufacturing execution, warehouse management, production management, data collection and monitoring, achieving the visualization of the manufacturing process, improving the efficiency and accuracy of warehouse operations, and collecting real-time data, achieving centralized control of production equipment, so as to improve production efficiency and quality, reduce costs and risks, and continue to enhance the competitiveness of enterprises. Starting from the whole process of delivery, Wiskind realizes the collaborative management of delivery, technology, procurement and PMC through the plan management system, creating an agile and efficient delivery system and laying a solid foundation for the smart factory. The integration of digitalization and intelligence is not only the trend of digital transformation in manufacturing, but also the key driving force for promoting new industrialization. With advanced technology and...

As the advanced metal envelope system supplier, Wiskind stresses on thermal insulation of products. We independently research and develop Colorpod ®, Colorgem ®, Colorcurtain ® and other sandwich panel wall products that use high-density thermal insulation fire retardant and water-repellent rock wool, achieving class A fire prevention and preventing fire effectively. Moreover, these products have got FM certification. It uses PU sealing on both sides. And the application of Wiskind’s new generation of interlaced double support joint, which can effectively block heat transmission, improve worker comfort and efficiency, protect equipment and products from high temperatures, and extend service life. Wiskind Acous® Sound Absorption and Insulation Sandwich Panel not only has thermal protection and insulation, but also has noise reduction. After the application, indoor noise reduction 1/3. For the cold chain industry, Wiskind’s Colorspar ® cold storage sandwich board has a unique advantage. It uses a new generation of polyurethane PIR pentane B1 foam as a hard core material, with ultra-high temperature stability and fire rating, excellent thermal insulation performance, and no freon emissions, which not only ensures indoor temperature stability, but also achieves energy saving and consumption reduction effect, and protects the summer cold storage project. In the future, Wiskind will also bring efficient and reliable building solutions to more factories through more technological innovation, and jointly move towards green and sustainable industrial development. Website:https://www.wiskindsteelstructure.com/ E-mail: market@wiskind.com Tel No: +86-18054651502

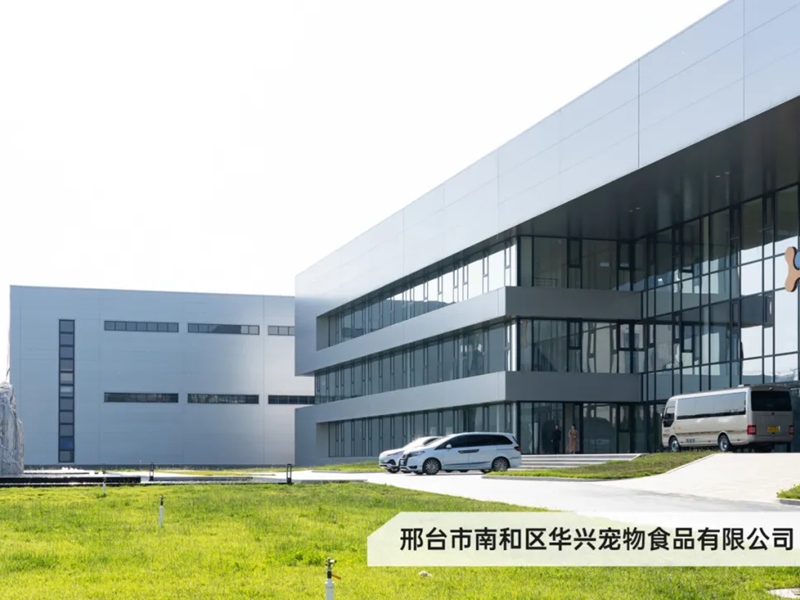

As an advanced and professional prefabricated cold storage envelope system supplier, Wiskind empowers the sustainable and intelligent development of factory by green building materials. This project applied Wiskind Colorspar® PU cold storage sandwich panel and cold storage fire partition special board. An the most optimum material of constructing various cold storage projects, colorspar® PU cold storage board has excellent thermal insulation and fire resistance. Polyurethane is combined with high-quality color coated steel plate or stainless steel plate, which can further improve the flame retardant property of the plate and excellent corrosion resistance. Cold storage and processing workshop inside applied cold storage fire partition special board, which is used as firewall and fire partition wall. Product core material preferred high quality 98% hydrophobic rock wool, with good thermal insulation performance and waterproof performance, can effectively prevent indoor and outdoor heat transfer. Besides, combined with Colorspar ®, it can effectively maintain the stability of indoor temperature. At the same time, the product also has excellent fire and flame retardant performance, which the fire rating reaches class A. The factory automation equipment will compound the steel plate and rock wool, and the reliability of the plate is higher. Colorspar ® PU cold storage board can be prefabricated in the factory. Besides, its installation system design is mature, and auxiliary accessories are perfect, which can make the site installation more simple and fast, greatly shorten the construction period, reduce the construction labor cost and material loss, promote the saving and recycling of resources. Adhering to the operation philosophy of Mutual Success Through Sincerity and Integrity, Wiskind will also adhere to technology and innovation to empower green buildings, constantly explore cutting-edge technologies, contribute to the construction of a green, low-carbon and sustainable cold chain environment, and lead the industry to create greater value.

The main structure of low-carbon park is prefabricated steel structure, and its outer layer is Colorpod® sandwich panel produced by Wiskind. Colorpod®, which has got FM certification, is a rock wool panel with PU sealing on both sides. It is center seams that connects panels. Its steel surface material is durable and environmentally friendly, combined with the thermal insulation effect of rock wool sandwich and the application of internal layer, forming a relatively complete air tightness, so that the building is more durable, environmental protection and energy saving. The overall horizontal bar design relies on Wiskind’s new generation of interlaced double support joint, and more accurate insertion precision brings smooth and beautiful visual effect. Through prefabrication production by Wiskind, and then lean construction on site, which not only shorten the construction cycle, reduce costs, but also achieve energy saving and carbon reduction, highlighting the advantages of prefabricated steel structure buildings. Based on low-carbon and energy-saving ideas, Wiskind will continuously explore new materials and technology, empowering manufacturing industry of China by high-quality metal envelope system, helping keep high-quality sustainable development of building trades. Website:https://www.wiskindsteelstructure.com/ E-mail: market@wiskind.com Tel No: +86-18054651502

In the process of construction, this project holds green development theory and chooses advanced supplier of metal construction envelope system——Wiskind. In this project, the external wall selected green building materials from Wiskind - Colorpod ® sandwich panel, which has passed the FM certification. The internal wall uses high-density thermal insulation fire retardant hydrophobic rock wool with excellent fire performance, good thermal insulation performance to ensure the maintenance of stable production temperature. In addition, the Colorpod ® sandwich panel uses Wiskind’s new generation of interlaced double support joint, and polyurethane edge sealing, bringing excellent airtight, watertight and wind resistance, to protect the project workshop. In this project, Wiskind also undertook its prefabricated steel structure project, and fully displayed the advantages of steel structure building environmental protection, energy saving, green recycling, excellent wind resistance and anti-earthquake performance, light weight and high strength, and fast construction speed. With the wall and roof assembly building materials mentioned above, they are all prefabricated by the factory and transported to the site, which can achieve rapid installation, showing the characteristics of efficient and accurate assembly installation. At the same time, the construction process can also greatly reduce the production of construction waste and pollutants, in line with the concept of sustainable development. Website:https://www.wiskindsteelstructure.com/ E-mail: market@wiskind.com Tel No: +86-0543-2165081

This project applied Colorgem Sandwich Panel self-developed by Wiskind, which has got FM certification. It uses 4-sided joint for high-precision installation, as well as a flat and refined visual effect. Colorgem sandwich panel applies PU sealing, prevent the core material from reducing strength due to moisture absorption. Meanwhile, its low thermal conductivity make its thermal insulation properties ever-lasting. Besides, it applies new generation of interlaced double support joint for super strong air tightness and zero thermal bridge conduction. It combines superior appearance and high performance to help building cope with climate impacts. As the industry's leading supplier of metal envelope systems, Wiskind will continue to lead the industrial development with scientific and technological innovation, empower China's manufacturing industry with green new materials, and create more green and sustainable quality projects for customers!

Please read on, stay posted, subscribe, and we welcome you to tell us what you think.

online service

online service +86-153 1435 3017

+86-153 1435 3017 market@wiskind.com

market@wiskind.com +86-153 1435 3017

+86-153 1435 3017