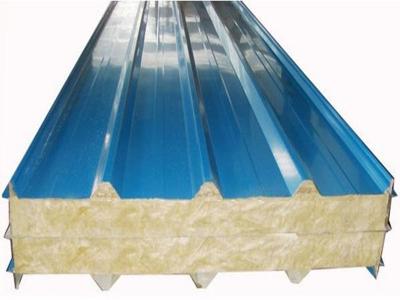

1 Product Parameters:

|

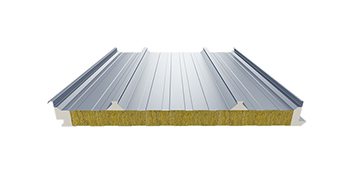

Steel Outer Layer

|

Common T (mm)

|

Outer Panel Specs 0.6-0.8(Coated Steel Panel)

|

|

|

|

Inner Panel Specs 0.4-0.7(coated steel panel)

|

|

|

Common L (mm)

|

≤12,000

|

|

|

Common W (mm)

|

500-1,100

|

|

|

Coating

|

PVDF/SRP/HDP/ PE

|

|

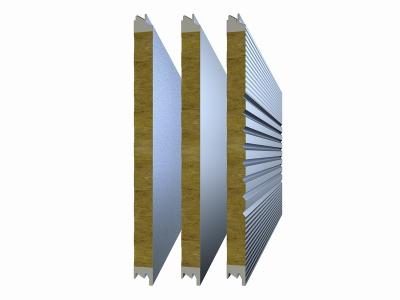

Insulation Core

|

Core Material

|

High-density thermal insulation, fireproof and

|

|

|

|

water-repellent rock wool/Glass Wool

|

|

|

VW (kg/m³)

|

Rock Wool: ≥120/Glass Wool: ≥64/PU (Edge Sealing):≥38

|

|

|

Thickness (mm)

|

50-150

|

|

|

TC (w/m·k)

|

Rock Wool:≤0.043 /Glass Wool:≤0.042

|

|

|

Fire Rating

|

Rock Wool: Class A /Glass Wool: Class A

|

|

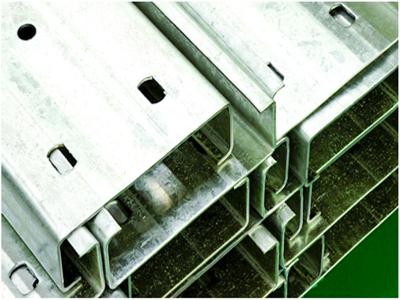

Process

|

Joint

|

2-sided joint-Male-Female Joint, PU Edge Sealing

|

|

|

Production Process

|

Continuous Production Process

|

|

|

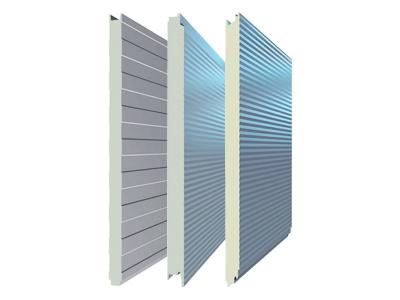

Surface Texture

|

Flat/Embossed Pattern/Micro Ripple/V8 RIPPLE

|

|

Center Trim Treatment

|

|

Metal Snap-in Cover Plate

|

|

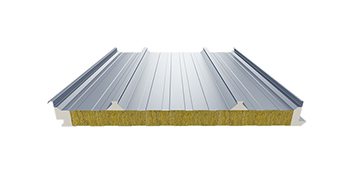

Upper steel plate style

|

|

3 Peaks

|

|

Joining method

|

|

Standing Seam

|

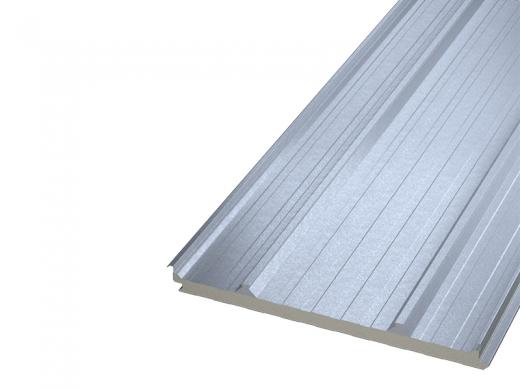

2 Product Characteristics:

PLATE ADVANTAGE

The hidden screws guarantee excellent waterproof performance and prevent screw corrosion and thermal bridge phenomena. The crest wave height is 34 mm. The three-crest wave design has improved the bearing capacity of poof panels, educed the amount of roof purlins, improved the bearing capacity and balanced the running water paction

PANEL UPGRADE

Roof Panel wave structure upgrade, can fix clamp directly, that makes installation of roofing photovoltaic solar and other systems easy and safe, promote effective utilization rate of roof.

The crest wave height is 34 mm. The three-crest wave design has improved the bearing capacity of roof panels,peduced the amount of roof purlines, improved the bearing capacity and balanced the running water action. The design of water tanks Ppevents water leakage.

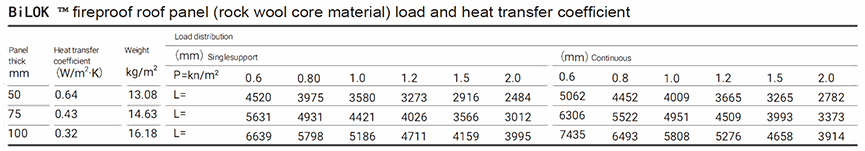

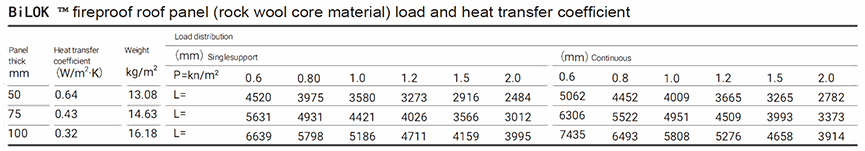

BiLOK ™(Standing Seam Rock Wool Roof Sandwich Panel with PU Edge Sealing) has a very good performance of fireproof roof panel (rock wool core material) load and heat transfer coefficient...

The above values are taken from the outer steel plate of 06mm, the inner steel plate of 0.5mm, and the rock wool bulk density of 120kg/m%. The plate type is 1000 type.

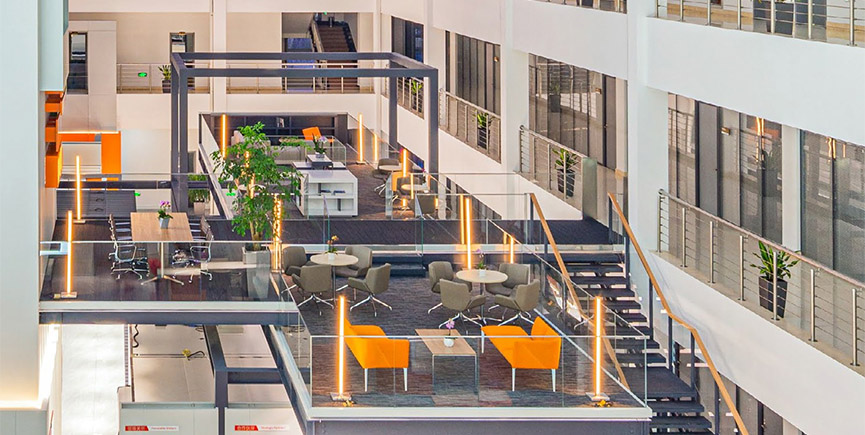

3 Product Philosophy:

Green Building Materials

More than 30 years ago, the 1st International Conference on Materials Science & Engineering put forward the concept of "green materials" for the first time, and the 14th Five-Year Plan has set the ambitious "dual" carbon reduction target. Today, various healthy, eco-friendly, and safe building materials are widely used. In the manufacturing process, rational use of resources, reduction of energy consumption, pollutant-free production, solid waste reduction, and full coverage management during the whole life cycle of materials have also become the consensus and code of conduct for the entire industry, reflecting people's yearning and pursuit of the "human-oriented and eco-friendly" development concept.

Building envelope is the most important category of green building materials. In this regard, Wiskind has gained rich practical experience, and mastered mature design, processing and application technologies, thus able to provide the client with a series of thermal insulation, waterproof, sound insulation, energy saving and aesthetic new composite wall panels. Wiskind researches and applies building envelope materials as a system, and pays attention to the design of structural systems, thereby effectively improving the overall performance of the product in the real-world application environment.

4 Manufacturing and Delivery:

Smart Manufacturing

Wiskind has multiple production bases across the country, and has introduced several world-class production equipment, such as PUMA/OMS/RAS, etc., to provide customized solutions for different application products and different production lines. The above equipment has high precision, precise processing, high automation level, convenient dynamic adjustment, fast response speed, high production efficiency, and is more green and environmentally friendly, providing good hardware support to produce high-quality plates.

Smart Delivery

With BIM building digital model, the four major industrial chains of intelligent design, intelligent manufacturing, intelligent logistics and intelligent construction are connected and closely linked.

5 Wiskind Builing Envelope Systems:

The building envelope consists of two major systems: the façade and the roof, which are linked up to the main structure through a reasonable form to realize the functions of heat preservation, waterproofing, sound insulation, energy saving and aesthetics of the building. The Wiskind envelope lineup enjoys a complete product system and a wide product range, including sandwich and profiled panels, as well as corresponding accessories, to provide the client with a total solution for building envelope systems. For more than 40 years, Wiskind has always been committed to the R&D, manufacturing and application of metal envelope products, constantly exploring new materials and new technologies, and providing hundreds of millions of square meters of various building envelope products for thousands of engineering projects, covering electronics, biology, medical care, automobile, food, modern agriculture & animal husbandry, warehousing & logistics, as well as transportation facilities, exhibition venues, and cultural & sports buildings, among other areas.

Building for Beauty and Eternity, for the Creation of a Better Life. The advancement of science and technology, the evolution of society, and people's yearning for a better life is an inexhaustible force that drives Wiskind to continue its development and shape the future.

English

English русский

русский español

español العربية

العربية 日本語

日本語 한국의

한국의 ไทย

ไทย Việt

Việt Indonesia

Indonesia українська

українська

online service

online service