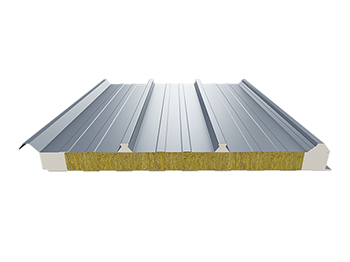

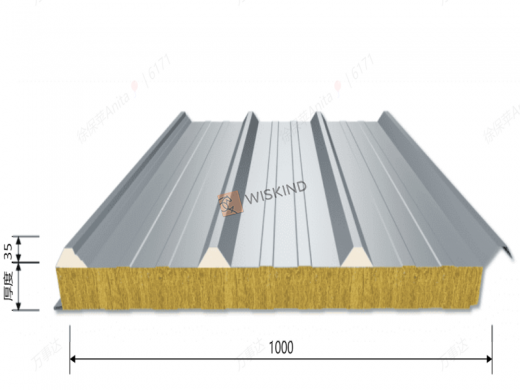

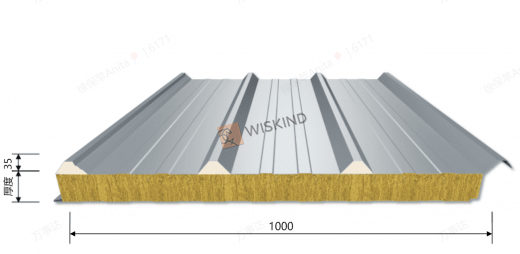

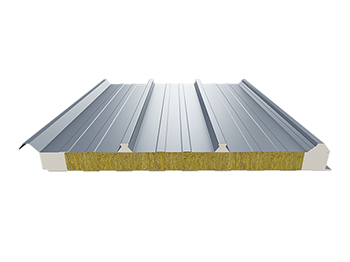

1 Product Parameters:

|

Steel Outer Layer

|

Common T (mm)

|

Outer Panel Specs 0.6-0.8(Coated Steel Panel)

|

|

|

|

Inner Panel Specs 0.4-0.7(coated steel panel)

|

|

|

Common L (mm)

|

≤12,000

|

|

|

Common W (mm)

|

500-1,100

|

|

|

Coating

|

PVDF/SRP/HDP/ PE

|

|

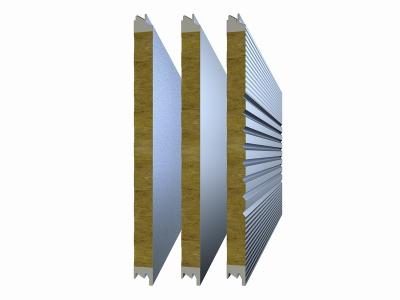

Insulation Core

|

Core Material

|

High-density thermal insulation, fireproof and

|

|

|

|

water-repellent rock wool/Glass Wool

|

|

|

VW (kg/m³)

|

Rock Wool: ≥120/Glass Wool: ≥64/PU (Edge Sealing):≥38

|

|

|

Thickness (mm)

|

50-150

|

|

|

TC (w/m·k)

|

Rock Wool:≤0.043 /Glass Wool:≤0.042

|

|

|

Fire Rating

|

Rock Wool: Class A /Glass Wool: Class A

|

|

Process

|

Joint

|

2-sided joint-Male-Female Joint, PU Edge Sealing

|

|

|

Production Process

|

Continuous Production Process

|

|

|

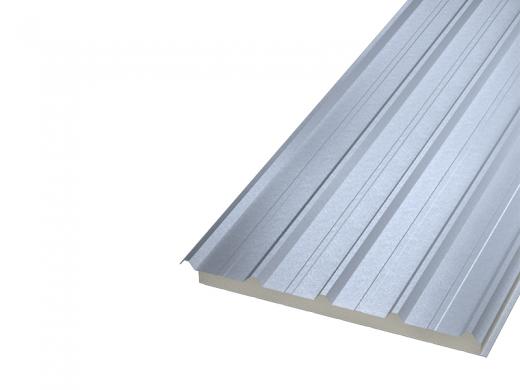

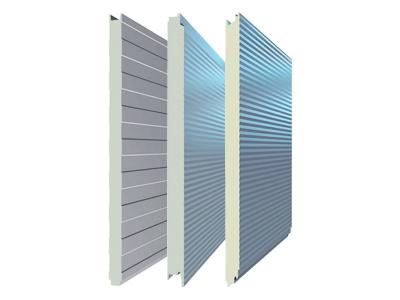

Surface Texture

|

Flat/Embossed Pattern/Micro Ripple/V8 RIPPLE

|

|

Center Trim Treatment

|

|

Metal Snap-in Cover Plate

|

|

Upper steel plate style

|

|

3 Peaks

|

|

Joining method

|

|

Over Lap

|

2 Product Characteristics:

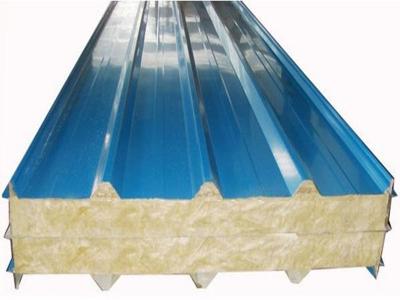

The hidden screws guarantee excellent waterproof performance and prevent screw corrosion and thermal bridge phenomena. The crest wave height is 34 mm. The three-crest wave design has improved the bearing capacity of roof panels, reduced the amount of roof purlins, improved the bearing capacity and balanced the running water action.

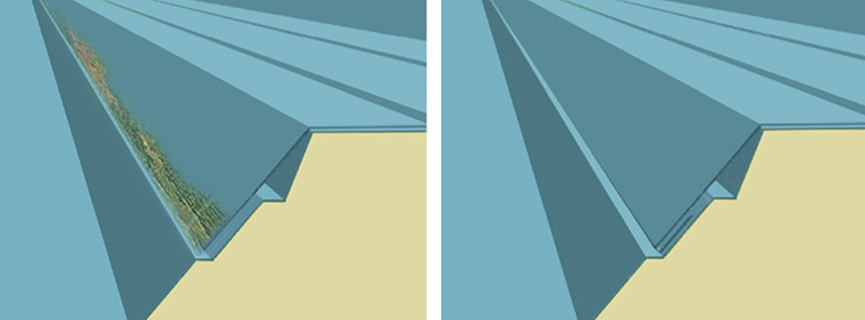

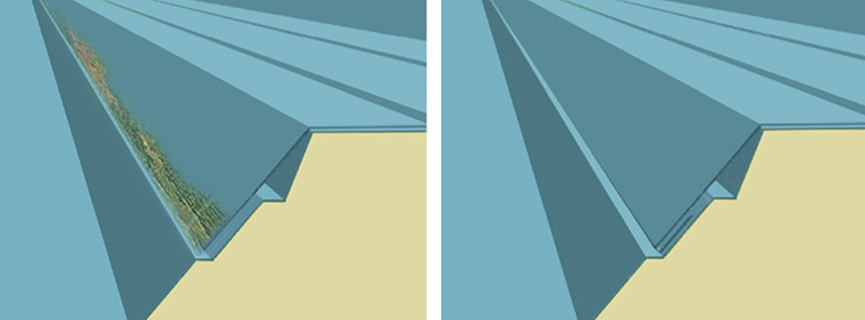

Without lapping design, the edge is corroded for the lack of coating after being soaked by rain water,which shortens the service life of roofing.

The lapping design features a closer lapping effect, protects the edges without coating and improves the service life of roofing.

3 Product Certificates:

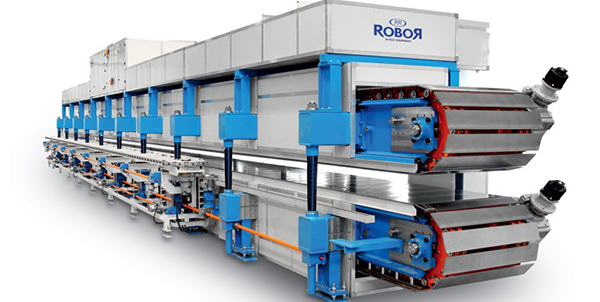

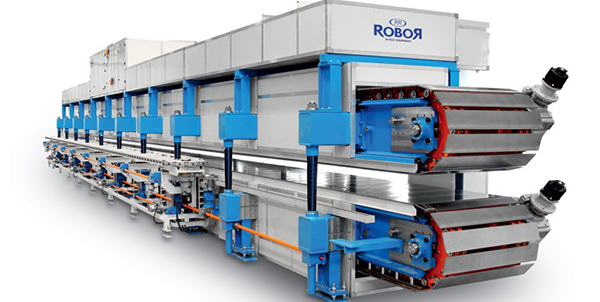

4 Production lines:

5 Product Philosophy:

Prefabricated Construction

Prefabricated Construction

Prefabricated building is an important achievement of the application of modern industrial technology in the field of construction, of which the concept was originated in the early 20th century and finally realized in Europe in the 1960s. In recent years, with the rapid development of materials, processes and information technologies, the advantages of prefabricated buildings in saving materials, quickening construction, reducing waste and optimizing functions have become increasingly prominent. Since 2015, the Chinese government has intensively promulgated a number of policies and regulations to promote prefabricated buildings across the country, which has achieved breakthroughs and become an important driver for the adjustment and upgrading of the industrial structure of China's construction industry.

Wiskind building envelope products follow the advanced concept of the prefabricated building. In terms of material structure, system design, process flow, etc., its exterior façade, roof and other product series bring the advantages of standardized design, factory processing, and modular construction of the prefabricated building into full play, while always maintaining the industry-leading level. At the same time, Wiskind attaches great importance to the organic combination of standardized products and customized designs, so as to meet the diversified and personalized needs of the client, and fully explore the aesthetic value of prefabricated buildings.

A complete set of imported Italian Puma production lines adopts European advanced polyurethane core production technology and six-component foaming process to ensure the stability of product performance. The extra-long double track ensures the flatness of the product surface. Based on digesting and absorbing foreign advanced technology, the brand-new BiLAP™ production line developed by Wiskind has obtained nearly 300 technical improvements, including two invention patents for bonding technology, rock wool conveying and lubrication system.

English

English русский

русский español

español العربية

العربية 日本語

日本語 한국의

한국의 ไทย

ไทย Việt

Việt Indonesia

Indonesia українська

українська

Prefabricated Construction

Prefabricated Construction

online service

online service