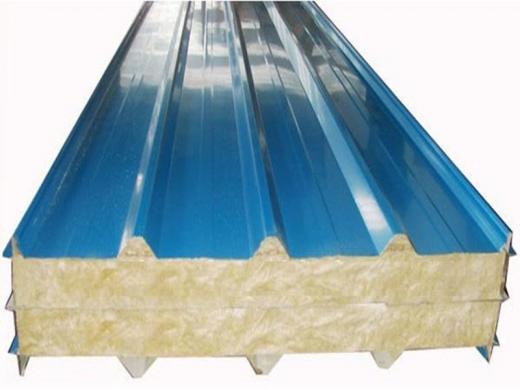

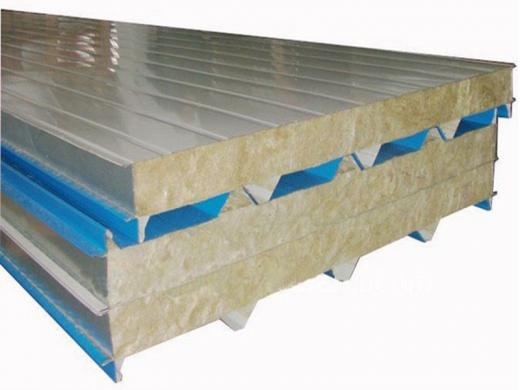

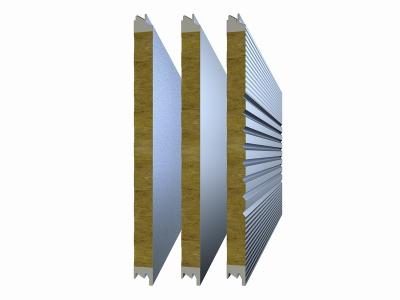

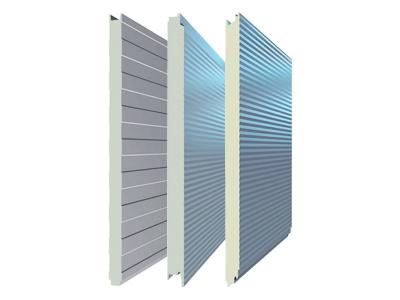

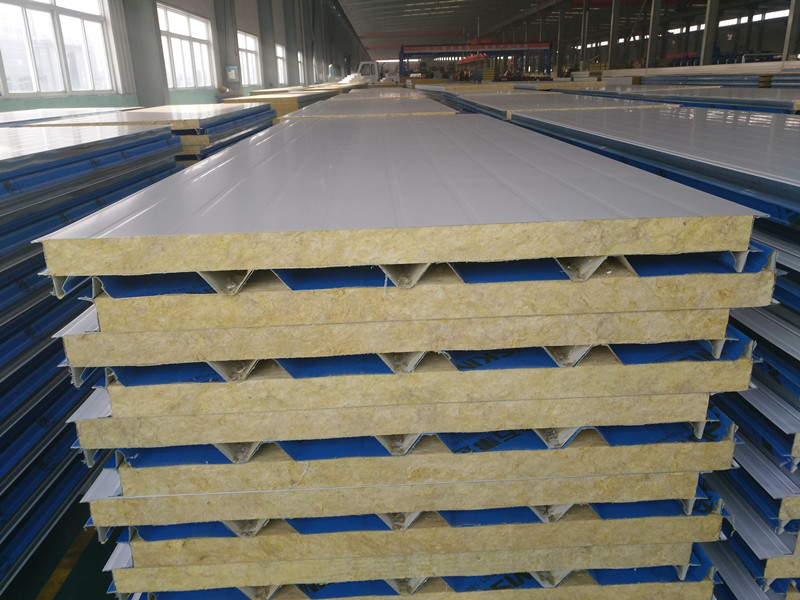

Standing Seam Rock Wool Roof Sandwich Panel with PU Edge Sealing

BiLOK ™ is a rock wool sandwich roof panels with pu sealing,it has a special standing seam. The standing seam is tightly engaged to provide effectivewaterproofness, airtight performance and stronger windresistance.

English

English русский

русский español

español العربية

العربية 日本語

日本語 한국의

한국의 ไทย

ไทย Việt

Việt Indonesia

Indonesia українська

українська

online service

online service