1 Product Parameters:

|

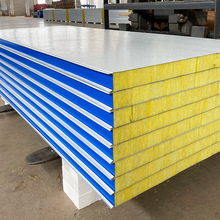

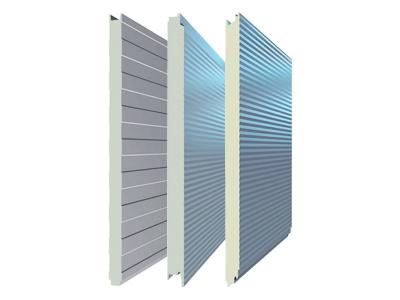

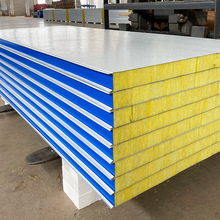

Steel Outer Layer

|

Common Thickness(mm)

|

Outer Panel Specs 0.6-0.8(Coated Steel Panel)

|

|

Outer Panel Specs 0.4-0.7(Coated Steel Panel)

|

|

Common Length(mm)

|

≤12000

|

|

Common Width(mm)

|

1000 as usual

|

|

Coating

|

PVDF/SRP/HDP/PE

|

|

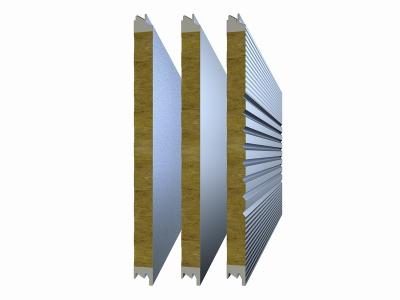

Insulation Core

|

Core Material

|

High-quality thermal insulation,fireproof and waterproof glass wool

|

|

Density(kg/M3)

|

Glass Wool≥64;PU(Edge Sealing)≥38

|

|

Thickness(mm)

|

50-150

|

|

U value(w/m·k)

|

Glass Wool: ≤ 0.042

PU (Edge Sealing): ≤ 0.026

|

|

Fireproof Rating

|

Glass Wool:Class A

|

|

Process

|

Joint

|

2-sided joint-Male-Female joint,PU Edge Sealing

|

|

Production Process

|

Continuous Production Process

|

|

Surface Texture

|

Flat/Embossed Pattern/Micro Ripple/V8 Ripple

|

|

Center Trim Treatment

|

Connection

|

Metal Snap-in Cover Plate

|

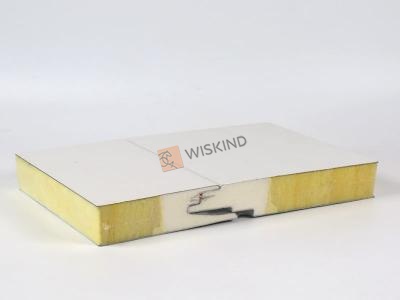

2 Product Characteristics:

(1) The glass wool sandwich panel has high closed cell rate and energy saving effect;

(2) Green and formaldehyde-free;

(3) One-time investment, continuous saving;

(4) The design of the plug-in interface makes it more resistant to negative wind pressure;

(5) Diverse shapes, beautiful and elegant advantages: no cold bridge, high rigidity, good flatness, glass wool grade A non-combustible;

(6) The plug interface is tight and there is no heat conduction of steel plate

(7) Polyurethane side seals on both sides to block the water absorption path of the core material and prolong the service life;

(8) The connection port design has stronger ability to resist negative wind pressure;

(9) Good fire performance: suitable for walls and roofs on large public buildings, industrial plants and other buildings that require fire protection.

Glass wool is a roll material made to meet the needs of large-scale laying. In addition to maintaining the characteristics of heat preservation and heat insulation, it also has excellent fireproof, shock absorption and sound absorption characteristics, which is conducive to reducing noise pollution and improving work. The environment is mainly used for: roof thermal insulation, roof thermal insulation, steel structure workshop wall thermal insulation, indoor thermal insulation and sound absorption, aquaculture roof thermal insulation and fire protection) thermal insulation, heat insulation, fire prevention, sound absorption, the effect is very ideal. It can also be arbitrarily cut as needed during construction, which has a good moisture-proof effect. It is a thermal insulation, heat insulation, fireproof and sound insulation material for workshops, roofs, walls and flat roofs.

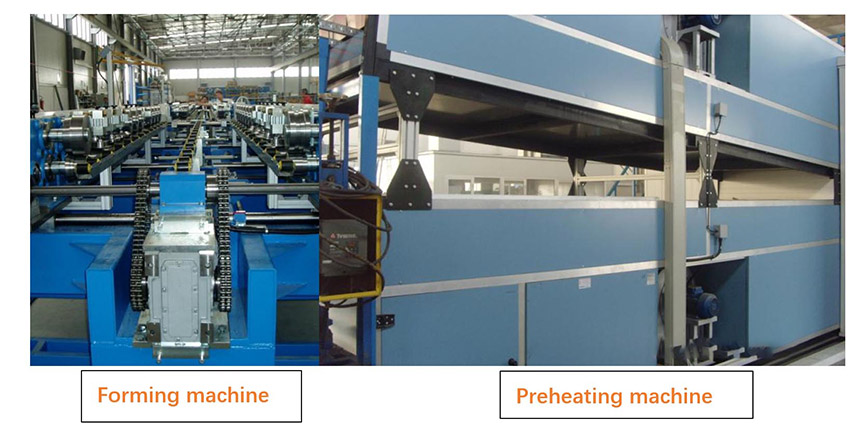

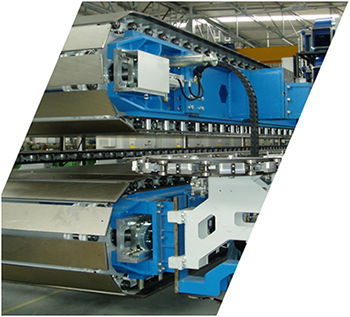

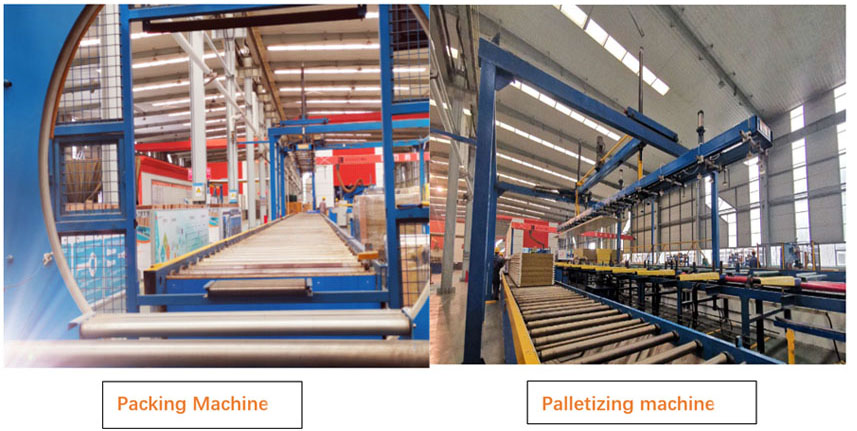

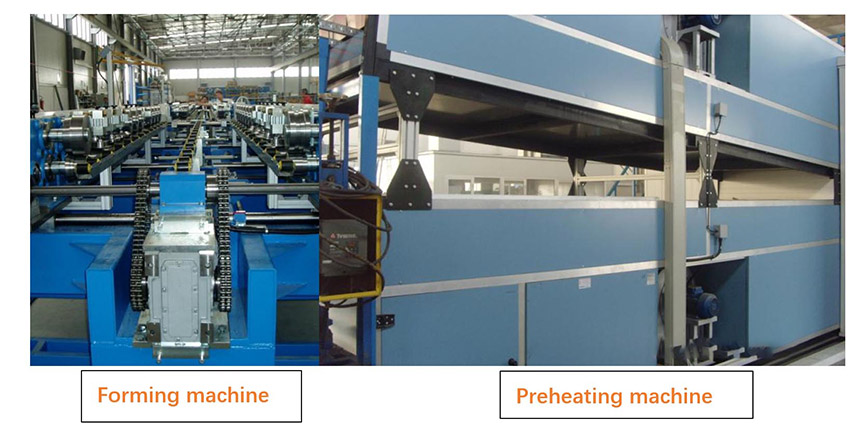

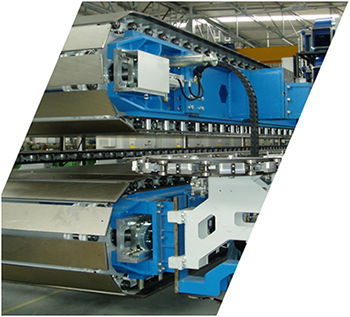

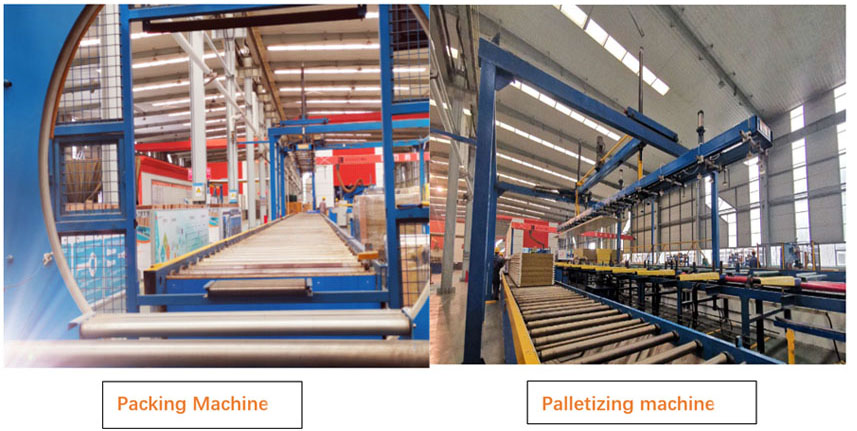

3 Production Mashines&Production Process:

Double track main equipment

lProduction speed: 5~8 m/min

lThickness: 40~200mm (wall panel); 50~150mm (roof panel)

lProduction speed: 5~12m/min

lThickness: 40~200mm (wall panel); 50~150mm (roof panel)

Generally, the main equipment of the manufacturer is only about 20m. The length of our mainframe is 26.3m. The ultra-long mainframe can increase the effective curing time by 30%, so that the core material is more fully cured, the performance of the board is more stable, and the quality is better.

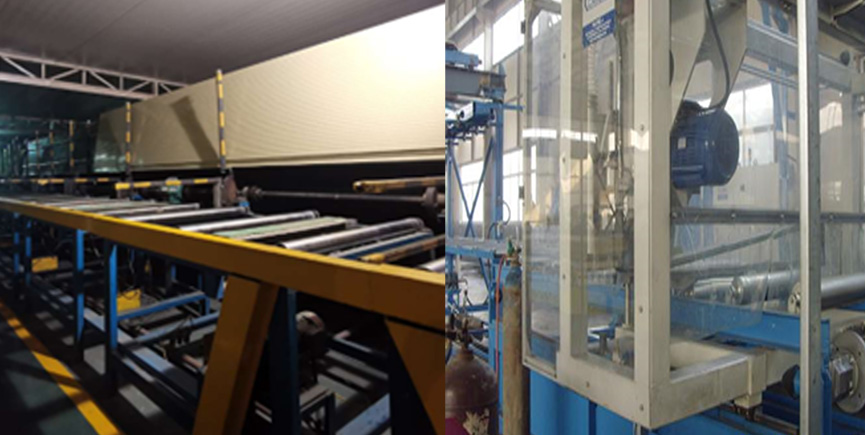

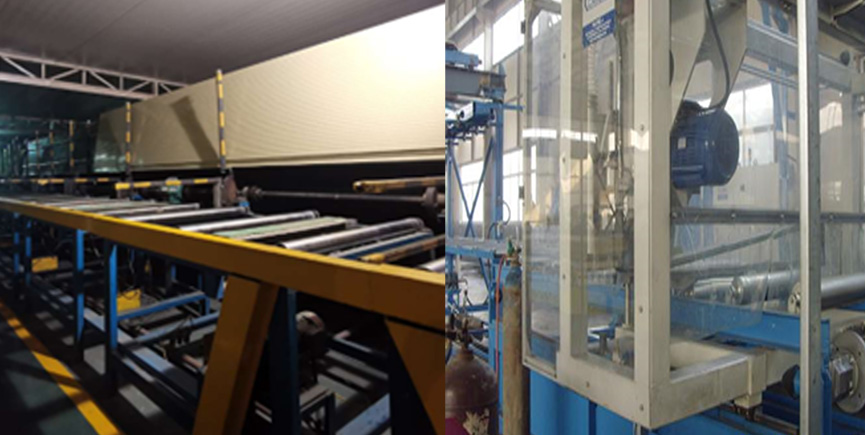

Cutting Machine

Automatic cutting length

16m≥L≥2m (usually)

cooling bed

Release the heat inside the core

Ensure uniform heat dissipation of the board

improve product quality

Single package ≤ 1.2m,Usually 1.1m per package

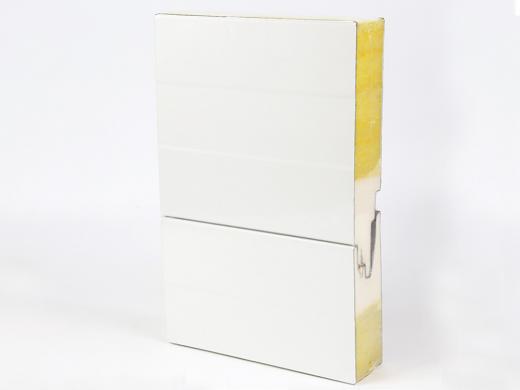

4 Production Packing&Shipping:

5 Company Advantages:

The core material is divided into two categories: rock wool polyurethane edge sealing and glass wool polyurethane edge sealing, which are characterized by:

1. The flame retardant performance grade reaches Class A, which improves the overall fire performance of the steel building.

2. Polyurethane is used as filling on both sides of the groove and mouth, which effectively reduces heat conduction and cuts off water leakage, preventing the fireproof cotton from reducing the strength and thermal insulation performance due to moisture absorption, and making the fireproof thermal insulation performance more durable.

3. High bulk density core material makes thermal insulation better

4. Both sides of the tongue and groove are filled with rigid polyurethane foam to enhance the overall strength and prevent deformation of the tongue and groove

5. The fireproof cotton is rotated 90 degrees, so that the cotton fiber and the board surface are in a vertical state, and the compressive and tensile strength is enhanced by more than 50%

6 FAQs:

1.Q:Are you manufacture factory or trading company ?

A: We are the factory have more than 40 years history.

2.Q: What’s the outside materials?Is it color steel?

A:The outer material can be prefabricated color-coated galvanized or galvanized aluminum steel plate, or aluminum-magnesium-manganese 3003/3015 material, and aluminum foil can be used as the inner plate.

3.Q: Is this sandwich panel fire resistant?

A:Yes,it’s fireproof materials,have passed FM approved.The fireproof grade is Class A.

4.Q:What’s your MOQ?

A:Can be negotiated according to your request.

5.Q:What’s your payment terms?

A: Usually 30% TT as deposit,should balance the payment before shipping.Also can accept LC at sight.

6.Q:What's the delivery time ?

A:It’s about 30 days.

English

English русский

русский español

español العربية

العربية 日本語

日本語 한국의

한국의 ไทย

ไทย Việt

Việt Indonesia

Indonesia українська

українська

online service

online service