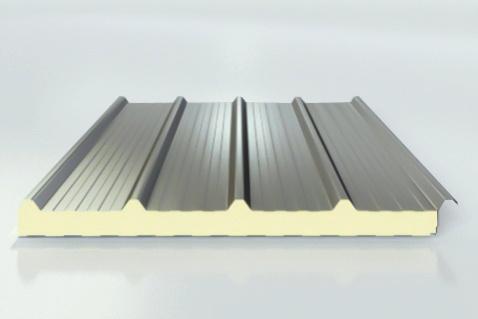

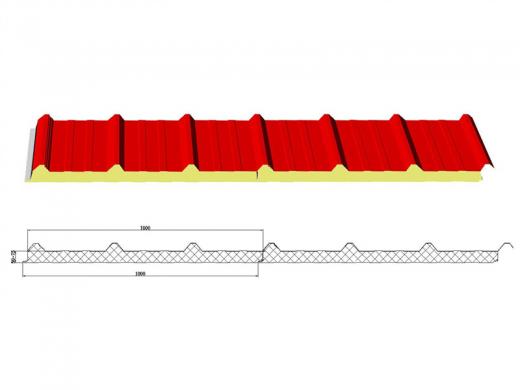

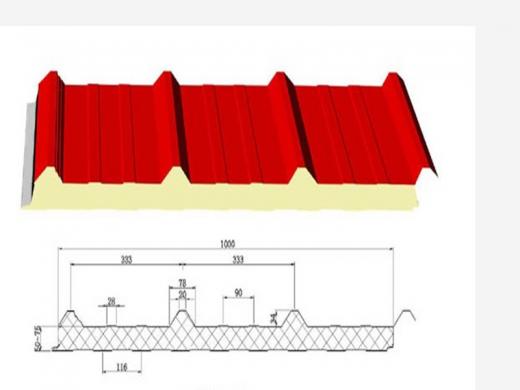

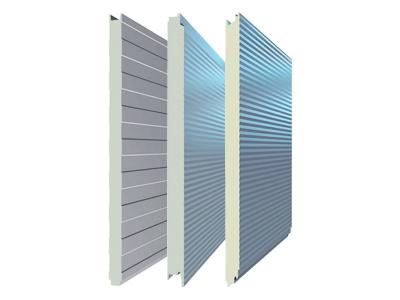

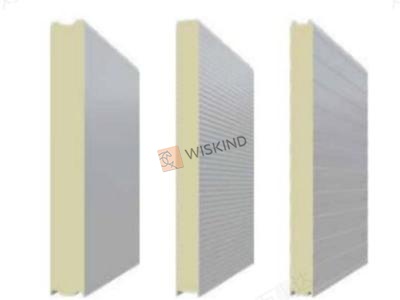

1000mm Over Lap Type PIR PU PUF Roof Sandwich Panels

Polyurethane is recognized as the most insulating material in the world,Wiskind use PU/PIR corial material to produce the Over Lap Type PIR PU PUF Roof Sandwich Panels. It has the advantages of best thermal insulation performance, class B fire resistance, light weight, non-toxicity, etc. It is widely used in the roofing of industrial steel structure buildings with high thermal insulation requirements, and the roofing of buildings in industries such as food and electronics.

English

English русский

русский español

español العربية

العربية 日本語

日本語 한국의

한국의 ไทย

ไทย Việt

Việt Indonesia

Indonesia українська

українська

online service

online service