780 Big Wave Wall Panel Corrugated Steel Wall Sheets

Wiskind 780 corrugated steel wall sheets is mainly used for wall panels, generally horizontally installed, beautiful in appearance and three-dimensional.

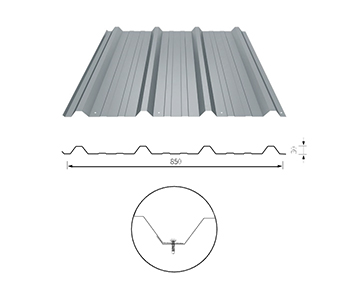

M850 Steel Wall Cladding Sheets is a special one with M-shaped side lap joint.It's unique M-shaped side lap structure, unique wall lines, good façade expression, suitable for large-scale buildings.

Payment:

TT/LCProduct Origin:

Shandong Province, ChinaColor:

Customized as your requestMOQ:

500 square metersShipping Port:

Qingdao Port, ChinaLead Time:

20-30s days after receiving your deposit1 Product Parameters:

|

Name of Product |

M850 |

|

Raw material width(mm) |

1000 |

|

Length(mm) |

850 |

|

Thickness(mm) |

0.53-0.8 |

|

Color |

Customed |

|

Material |

Color-coated coils, aluminum-zinc-magnesium plates, aluminum alloy plates, stainless steel plates |

2 Product Characteristics:

(1) Unique M-shaped side lap joint structure, unique wall lines, good facade expression, suitable for large-scale buildings

(2) 0 end pre-punched screw holes (only one end is punched, Ø5, 25mm from the end),

The raw materials are usually 0.53-0.8mm thick, 300 or 350MPa strength aluminum-zinc color-coated steel plate

(3) 550MPa high-strength materials and stainless steel can be used

(4) Fast installation, economical and practical

3 Product Production Machines:

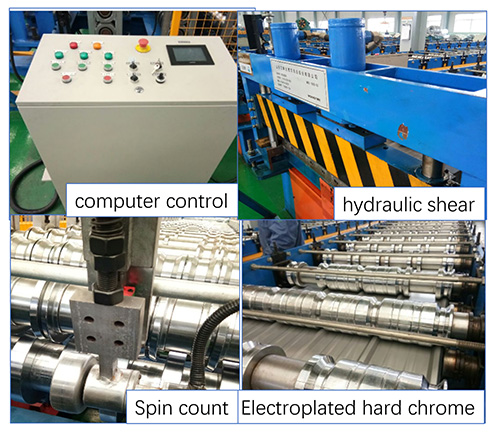

1. Fully automatic computer control, frequency conversion stepless speed control, hydraulic forming mold scissors shear.

2. The sheet is fed from the discharge frame and enters the main machine roll forming through the main machine guide device, with rotary encoder to measure the length, and its pulse signal is fed back to the computer board, and then the computer controls the main motor.

3. When the plate line out of the scissors, about 0.6-0.8 meters from the set size, the motor slowly decelerates, when the set size is reached the motor stops, the hydraulic cylinder action and cut off the type plate, after reaching the lower limit of the hydraulic cylinder reset and drive the scissors to reset, this time the machine completes a single cycle operation.

How to reduce the damage to the material in the molding process, shear fracture of

4. The production process of pressing, cutting, sizing and piece count can be completed at one time.

5. The equipment is lengthened, and the surface of the roll is electroplated with hard chrome, which has high hardness and surface finish to improve the service life of the roll and can avoid the surface of the press plate from being scratched.

3 Features of Wiskind Industrial Building Envelope Type:

1. There are many types of plate shapes

There are up to 15 kinds of recommended common panel shapes, including 3 kinds of roof panels, 8 kinds of wall panels, 2 kinds of lining panels, and 3 kinds of roof bottom plates.

2. Wide coverage of waveform

In order to meet the effect requirements of different buildings' external facades, in addition to the ordinary trapezoidal broken line and wave plate type, the wall panel type also includes unique plate types such as asymmetric wave and broken line waveform.

3. High degree of modularization

In order to improve the standardization and modularization of building products, a number of different panel shapes have the same modulus; the modulus of multiple panel shapes with different uses is coordinated, and can be reasonably combined into an enclosure system with excellent performance.

4. Various connection methods

We strive for perfection in details. In the construction of the lap joints of the panels, waterproof and aesthetics are all considered. In addition to the traditional exposed screw connection, in order to improve the integrity of the building façade, multiple wall panels provide a unique "hidden button-type hidden screw connection".

4 The Application of Corrugated Steel Sheets:

Mainly used for steel building maintenance, or other structural maintenance

1. Various roof and wall decoration

2. Interior and exterior decoration materials

3. Floor structure of civil residential buildings

4. Workshop

5. Public buildings such as gymnasiums, exhibition halls, railway stations, airports, etc.

Note: It can be combined with various insulation materials and various bottom layers to form insulation or non-insulation roofs

Please read on, stay posted, subscribe, and we welcome you to tell us what you think.

online service

online service +86-153 1435 3017

+86-153 1435 3017 market@wiskind.com

market@wiskind.com +86-153 1435 3017

+86-153 1435 3017