Modular Cleanroom Sandwich Wall Panels For Pharmaceutical Clean Room

Product Description:

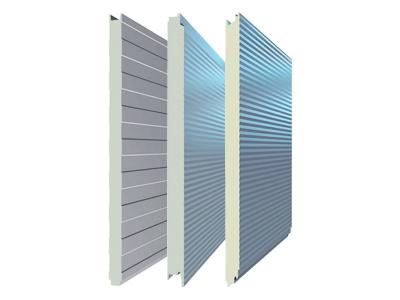

|

Product Name

|

Modular Cleanroom Sandwich Wall Panels For Pharmaceutical Clean Room

|

Width

|

980mm,1180mm

|

Max Length

|

7500mm

|

|

Wall Thickness

|

50mm, 75mm, 100mm, 150mm

|

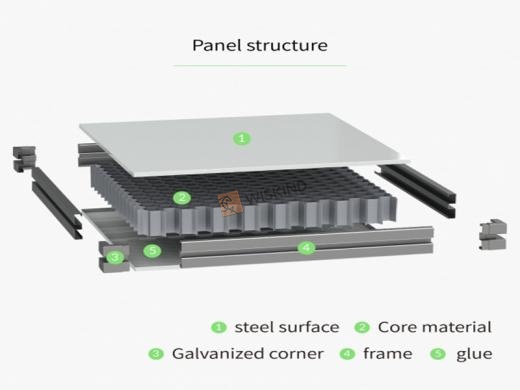

Steel Facer Thickness

|

0.4-0.8mm

|

|

Outer Plate Material

|

PPGI, Al-mg-Mn Alloy Steel, SS Steel, Ti-Zn Steel, HPL, VCM

|

|

Coating

|

PE, PVDF, HDP

|

|

Core Material

|

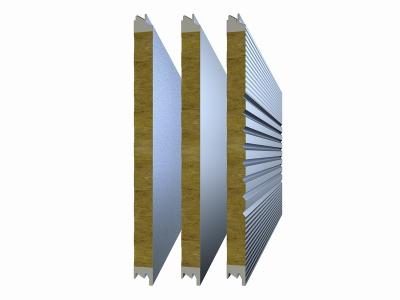

PU, Rock Wool, Magnesium Board, Paper Honey Comb, Aluminium Honey Comb, Plaster, EPS, etc.

|

Frame Thickness

|

0.6-0.8mm

|

|

Application

|

Pharmaceutical Clean Room, Electronic Clean Room, Food Clean Room, etc.

|

1.Core material fire rating can be viewed.

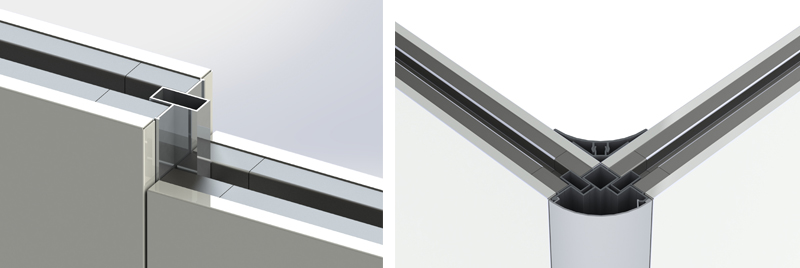

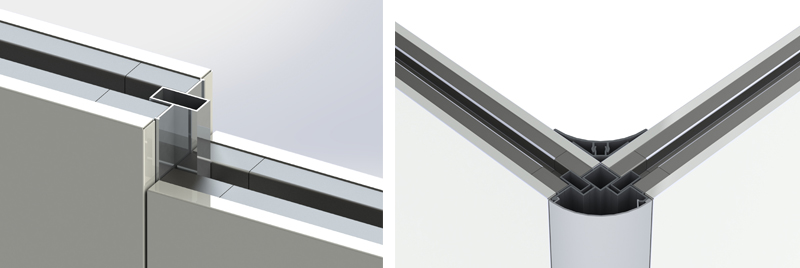

2.The cleanroom sandwich wall panel system is used with aluminum profiles, modular installation, convenient and fast, non-standard sandwich panels can be customized.

3.Factory accepts customization.

4.Diversified core material for different environments, fire protection, insulation, noise reduction, moisture resistance.

5.The factory offers 6 different steel to provide customers with more services.

6.The cleanroom wall panel, strength, flatness and aesthetics of the cleanroom board are greatly improved, and the product quality is more stable.

7.The hole reinforcement reservation and the line pipeline box are pre-assembled into the interior of the board in the factory, effectively reducing the secondary pollution during use, especially in the operating room.

Production Technology:

1.Self-developed and researched No.1 Automatic production line for cleanroom sandwich wall partition systems.

2.High-efficiency production line increases production capacity by 6 to 8 times.

3.Accurately measure and control sheet metal forming, gluing, core filling, composite molding and finished palletizing.

English

English русский

русский español

español العربية

العربية 日本語

日本語 한국의

한국의 ไทย

ไทย Việt

Việt Indonesia

Indonesia українська

українська

online service

online service