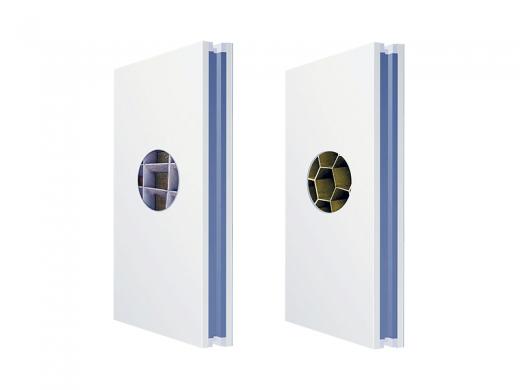

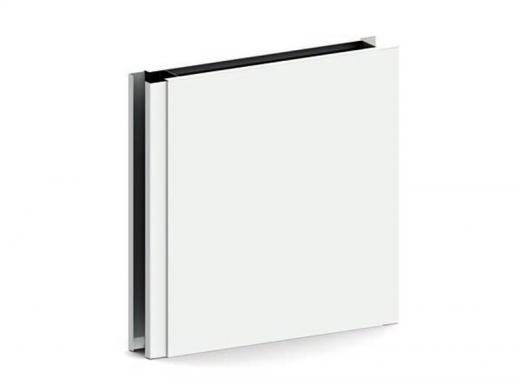

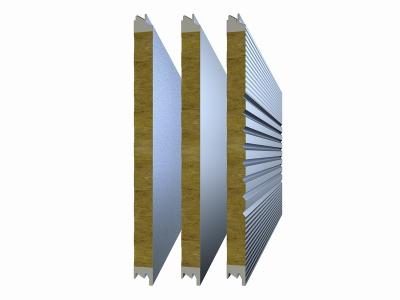

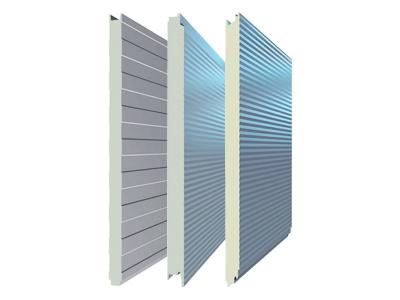

Modular Cleanroom Sandwich Wall Panels For Pharmaceutical Clean Room

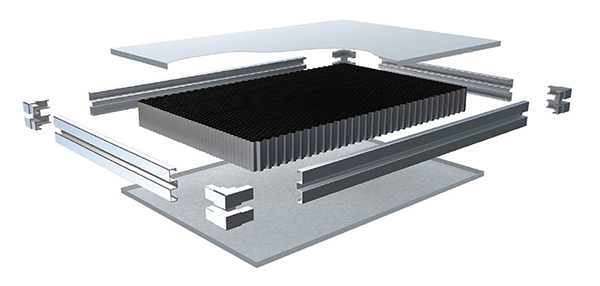

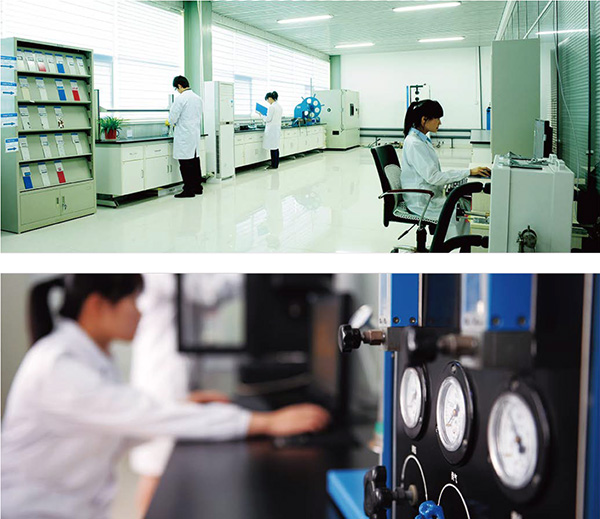

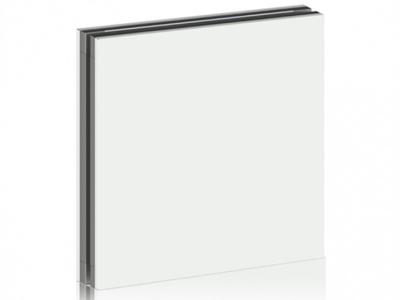

The modular cleanroom sandwich wall panel system is made of aluminum profiles, various surface steel, factory prefabrication, on-site splicing, modular installation is convenient and fast, mainly used in operating clean room, can be customized according to your different needs.

English

English русский

русский español

español العربية

العربية 日本語

日本語 한국의

한국의 ไทย

ไทย Việt

Việt Indonesia

Indonesia українська

українська

online service

online service