1 Product Parameters:

|

Steel Outer Layer

|

Common Thickness(mm)

|

Specs 0.5-0.8(Coated Steel Panel)

|

|

|

Inner Panel Specs 0.46-0.7(Coated Steel Panel)

|

|

Common Length(mm)

|

≤15000

|

|

Common Width(mm)

|

920-1120

|

|

Coating

|

PVDF/HDP/PE

|

|

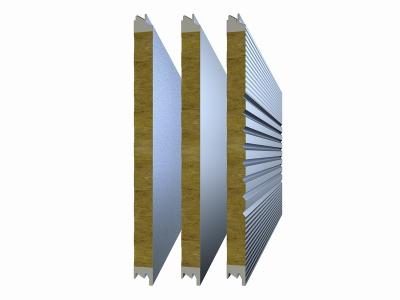

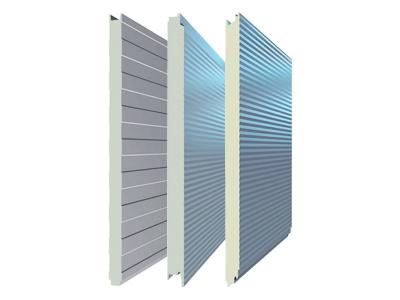

Insulation Core

|

Core Material

|

PU

|

|

Density(kg/M3)

|

PU:40±2

|

|

Thickness(mm)

|

50-200

|

|

U value(w/m·k)

|

PU:≤0.024

|

|

Fireproof Rating

|

PU:Class B1

|

|

Process

|

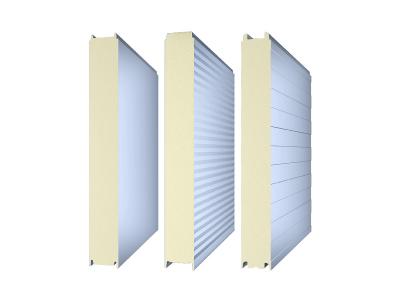

Joint

|

2-sided joint-Male-Female Joint

|

|

Production Process

|

Continuous Production Process

|

|

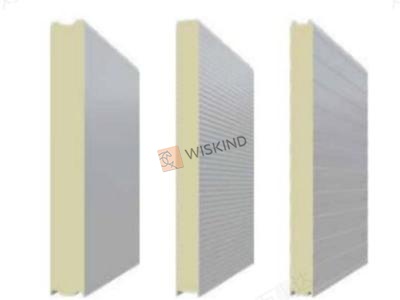

Surface Texture

|

Flat/Flat Ribbing/Micro Ripple

|

|

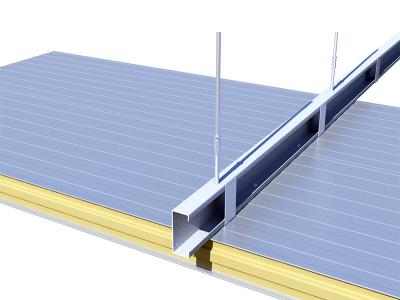

Center Trim Treatment

|

Connection

|

PU Filing+Decorative Cover

|

|

Application

|

Insulated Sandwich Panels for Low Temperature Meat

Frozen Cold Storage Room

|

2 Product Characteristics:

Polyurethane/polyisocyanurate sandwich panel is currently the most widely used cold storage enclosure material. The core material is rigid polyurethane foam. Its main advantages are: small thermal conductivity, strong thermal insulation performance, good overall performance, and foam pores. High sealing rate, low water absorption rate, high bonding strength, and aging resistance of more than 25 years. So more and more customers are using it.

WISKIND is committed to the research and development of cold chain business, and introduces professional production equipment from OMS company in Italy to provide first-class insulation system for your cold storage.

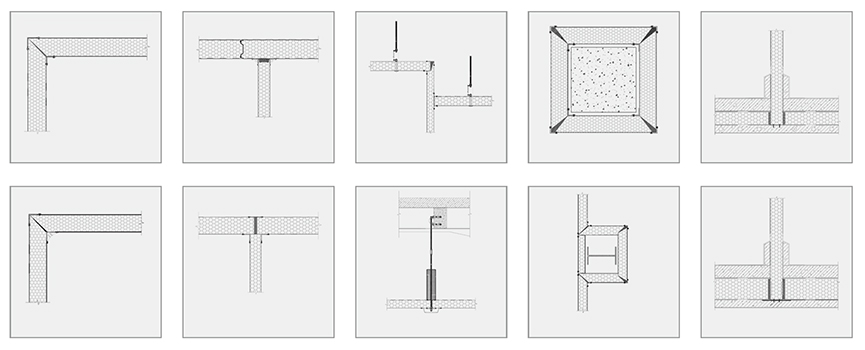

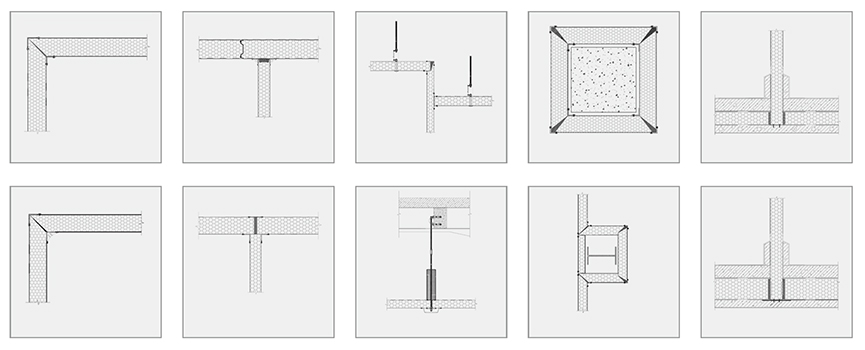

3 Product Installation Process:

--Outer ground node product installation process

4 Meat Frozen Cold Room Product Project Cases:

---Meat Frozen Cold Room Project Cases of Tianjin Baiken Food Technology Co., Ltd.

---Meat Frozen Cold Room Project Cases of Yantai COFCO Workshop Renovation

---Meat Frozen Cold Room Project Cases of Muyuan Elevated Library Project

English

English русский

русский español

español العربية

العربية 日本語

日本語 한국의

한국의 ไทย

ไทย Việt

Việt Indonesia

Indonesia українська

українська

online service

online service