1 Product Parameters:

|

Steel Outer

Layer

|

Common T (mm)

|

Outer Panel Specs 0.6-0.8(Coated Steel Panel)

|

|

Inner Panel Specs 0.4-0.7(Coated Steel Panel)

|

|

Common W (mm)

|

500-1,100

|

|

Coating

|

PVDF / SRP / HDP / PE

|

|

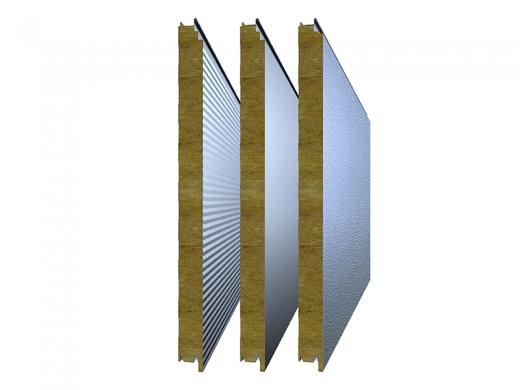

Insulation Core

|

Core Material

|

High-density thermal insulation,

|

|

fireproof and water-repellent rock wool

|

|

VW (kg/m³)

|

Rock Wool: ≥ 120

|

|

Thickness (mm)

|

50-200

|

|

U Value (w/m·k)

|

Rock Wool: ≤ 0.043

|

|

Fire Rating

|

Rock Wool: CLASS A

|

|

Process

|

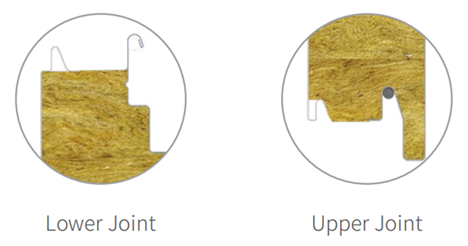

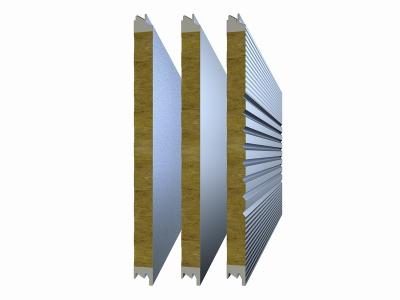

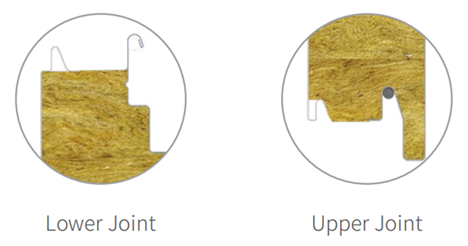

Joint

|

2-sided joint-Male-Female Joint

|

|

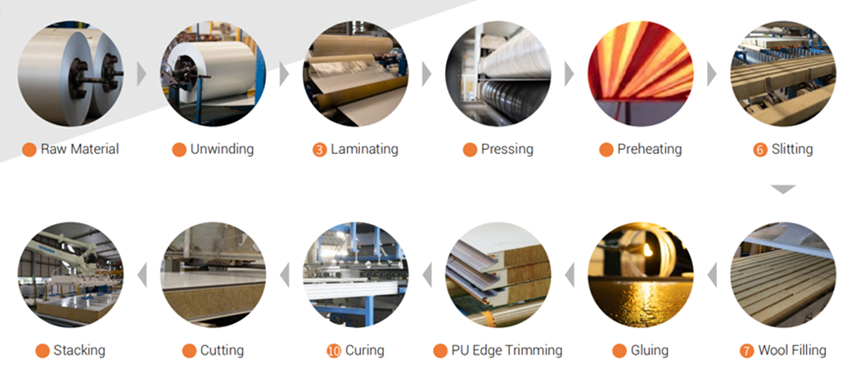

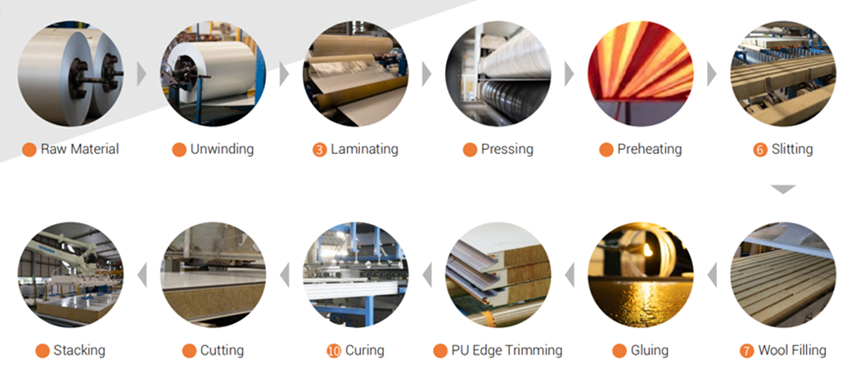

Production Process

|

Continuous Production Process

|

|

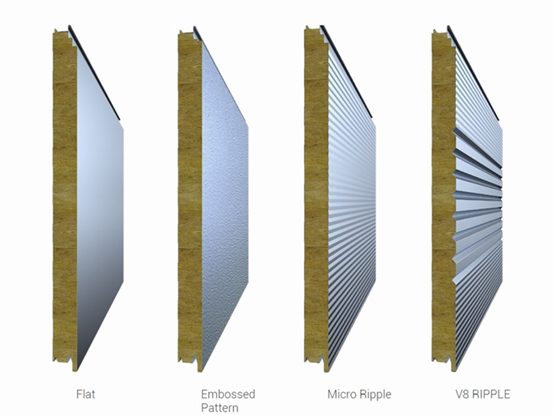

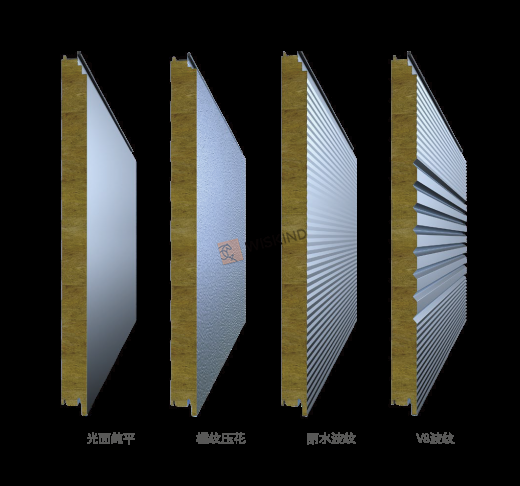

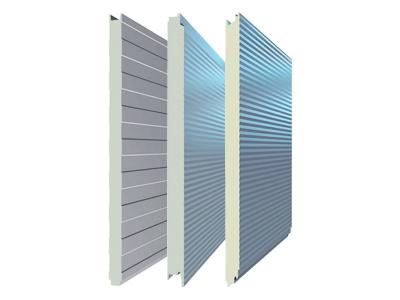

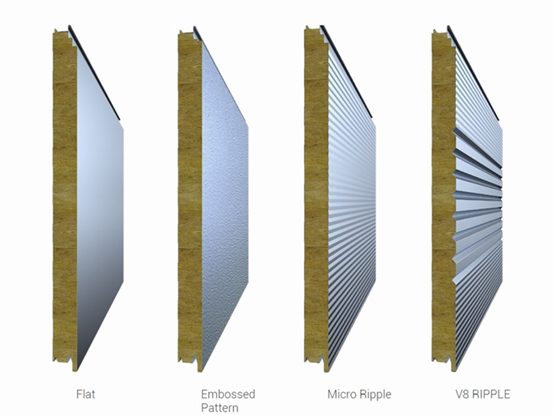

Surface Texture

|

Flat / Embossed Pattern

/ Micro Ripple / V8 RIPPLE

|

|

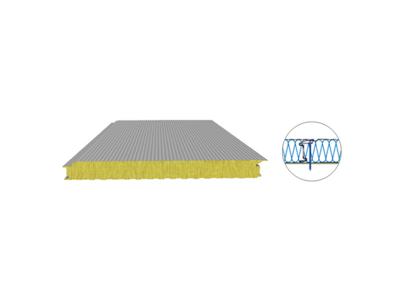

Center Trim Treatment

|

|

Metal Snap-in Cover Plate

|

2 Product Design:

-All-new dual-support plug-in structure, short outer overhang, improved wind resistance;

-Unique reinforced gasket of Wiskind to strengthen support, ensure the strength and flatness of the joint after installation, and improve the wind resistant performance.

-Cavity rainscreen design for better waterproof and air-proof performances;

-The rock wool joint is designed to fit tightly for better air insulation and heat preservation;

-Slow rebound foam tape to improve the airtight and watertight performances of the joint;

-Offer effective sound insulation to reduce noise disturbance.

3 Product Description:

1. Fire resistance: The rock wool core material is a different material and has a sintering temperature of more than 1000 degrees, which can effectively block the spread of flames in a fire and minimize fire losses;

2. Thermal insulation and energy saving: rock wool has low thermal conductivity and good thermal insulation performance. Excellent node design to ensure sealing performance and thermal insulation effect

3. Good sound insulation: good sound insulation, sound insulation ≥ 30dB, effectively reducing the interference of external noise

4. Water-tightness and air-tightness: The plates are designed as unique interlocking nodes to prevent the intrusion of water; the end connections of the plates are sealed inside to maintain good air-tightness.

5. Sturdy and durable: high-quality rock wool material is selected, which has a large water repellency rate and is durable and sturdy.

6. Beautiful façade: screw hidden node design, high flatness of the board surface, rich colors of the baking paint coating, and long-lasting color.

4 Product Project Case:

5 Production Process:

6 FAQ:

1. Who are we?

We are based in Shandong, north of China, start from 1978, It has 43 years of history and experience, and our customers come from all over the world.

2. How can we guarantee quality?

All raw materials are from high-quality domestic and foreign suppliers;

All production links must be strictly controlled;

All products must be strictly inspected before leaving the factory;

All customer after-sales service has a special person responsible.

3.What is the minimum order quantity?

1000 meters minimum order.

4. What services can we provide?

Accepted Delivery Terms: FOB,CFR,CIF,EXW,FAS,DDU,Express Delivery;

Accepted Payment Currency:USD,EUR,RMB and so on;

Accepted Payment Type: T/T,L/C.

5. where can it be used?

Office buildings, commercial buildings, industrial plants, etc.

English

English русский

русский español

español العربية

العربية 日本語

日本語 한국의

한국의 ไทย

ไทย Việt

Việt Indonesia

Indonesia українська

українська

online service

online service