1 Product Parameters:

|

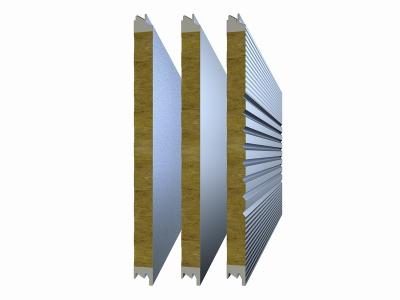

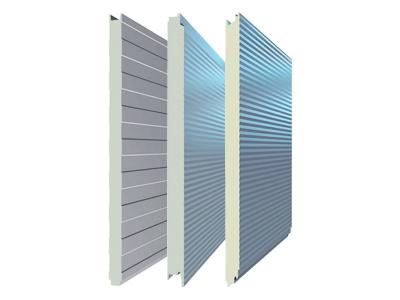

Steel Outer Layer

|

Common Thickness(mm)

|

Outer Panel Specs 0.6-0.8(Coated Steel Panel)

|

|

Outer Panel Specs 0.6-0.8(Coated Steel Panel)

|

|

Common Length(mm)

|

≤12000

|

|

Common Width(mm)

|

500-1000

|

|

Coating

|

PVDF/Huicai/HDP/PE

|

|

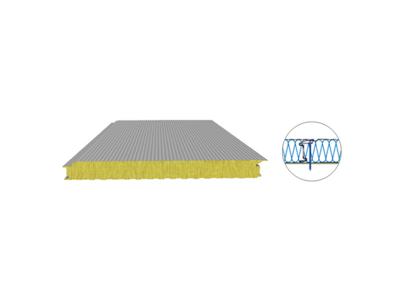

Insulation Core

|

Core Material

|

High-quality thermal insulation,fireproof and waterproof rock wool/glass wool

|

|

Density(kg/M3)

|

Rock Wool≥120;Glass Wool≥64;PU(Edge Sealing)≥38

|

|

Thickness(mm)

|

50-150

|

|

U value(w/m·k)

|

Rock Wool: ≤ 0.043 / Glass Wool: ≤ 0.042

PU (Edge Sealing): ≤ 0.026

|

|

Fireproof Rating

|

Rock Wool:Class A;Glass Wool:Class A

|

|

Process

|

Joint

|

4-sided joint,PU Edge Sealing

|

|

Production Process

|

Continuous Production Process

|

|

Surface Texture

|

Flat/Embossed Pattern/Micro Ripple/V8 Ripple

|

|

Center Trim Treatment

|

Connection

|

Metal Snap-in Cover Plate

|

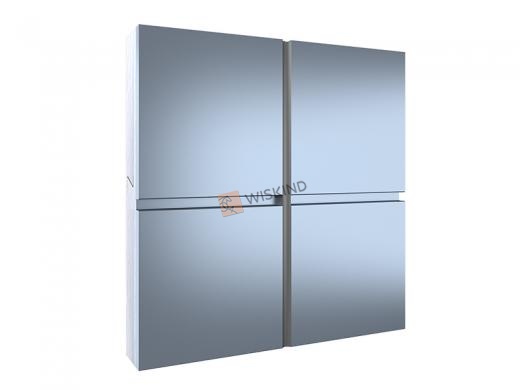

2 Product Characteristics:

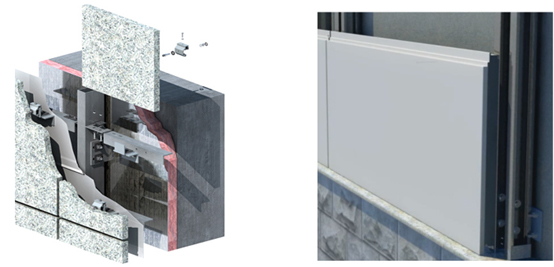

l New generation of interlaced dual-support joint for super strong wind resistance, air tightness, and zero thermal bridge conduction.

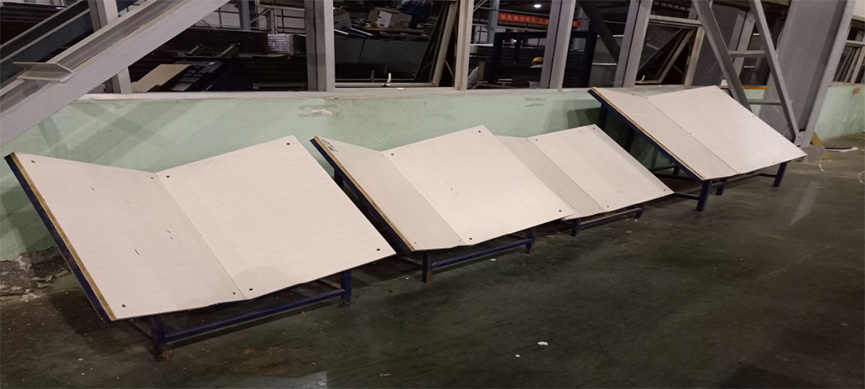

l Continuous line for high-efficiency production.

l Closed cavity to prevent water seepage, watertight & airtight.

l Prefabricated foam, edge sealed with PVC + aluminum foil, more waterproof and economical.

l PU edge sealing to prevent the core material from strength reduction due to moisture absorption, and at the same time, the thermal conductivity is quite low, thereby a more durable insulation performance.

The color gem adopts a prefabricated four-sided protective modular structure, which is structurally waterproof, air-tight, and fully and effectively protects the core material to avoid water ingress due to poor sealing. The integrated design avoids cumbersome processes such as multi-layer materials and multi-layer construction.

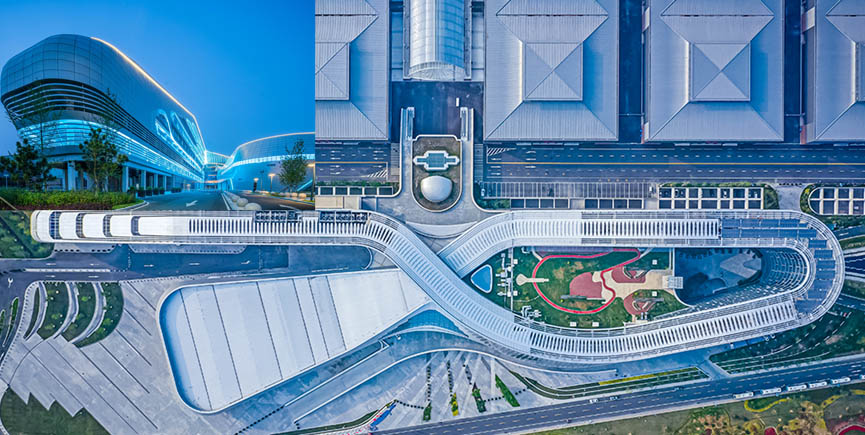

3 Product Project Cases:

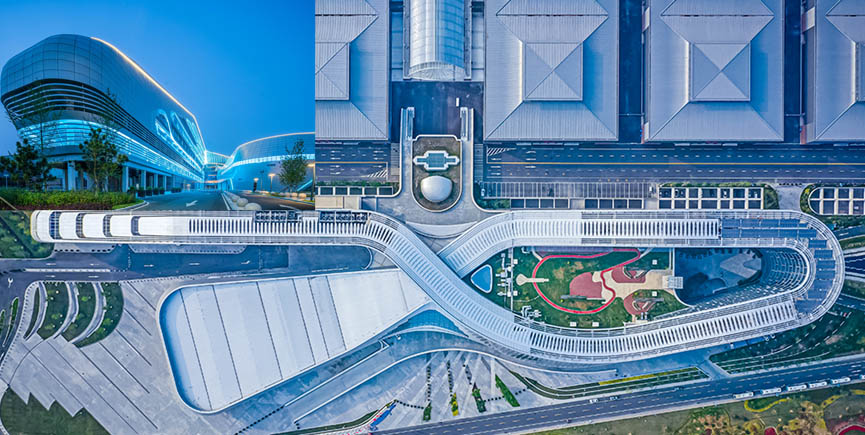

--4-sided joint Rock Wool Sandwich Panel with PU Sealing Product Case of Qingdao World Expo City

--4-sided joint Rock Wool Sandwich Panel with PU Sealing Product Case of Nanjing Kangmai Machinery

--Product Case of Qingdao Xiaojianxi Waste-to-energy Plant

4 Packing&Shipping:

5 Company Technical Advantage:

Freely customized one-piece 90° corner board, seamless corner, more beautiful!

Products can be customized to meet diverse customer requirements--Chamfered board.

Meet the needs of the production of different angle corner boards.

6 Product Knowledges:

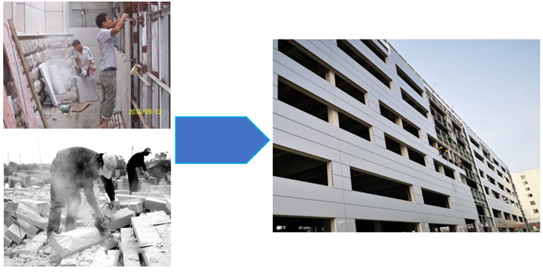

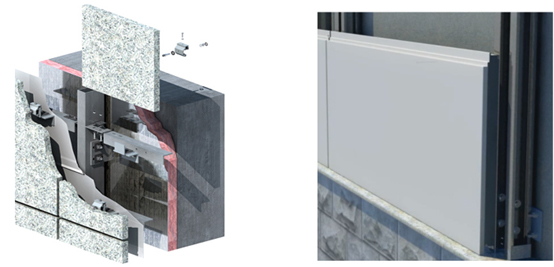

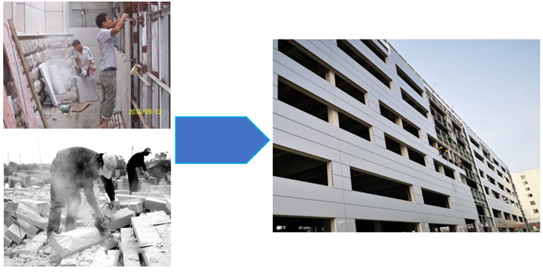

Comparison between traditional stone installation and Color Gem installation

The traditional stone curtain wall construction is cumbersome, relying on labor, the cost is relatively large, and the pollution is serious.

Improve the thermal insulation performance, the board is as flat as a mirror, shorten the construction period to avoid on-site garbage, facilitate recycling and maintenance, and reduce the dependence of engineering quality on labor.

English

English русский

русский español

español العربية

العربية 日本語

日本語 한국의

한국의 ไทย

ไทย Việt

Việt Indonesia

Indonesia українська

українська

online service

online service