1 Product Parameters:

|

Whole Thickness

|

50mm, 75mm, 100mm

|

|

Max Length

|

9000mm

|

|

Ceiling Panel Length Suggested

|

≤3500mm

|

|

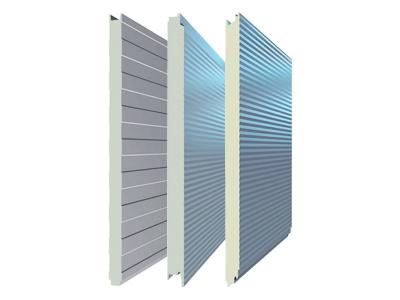

Standard Width

|

980mm, 1180mm, 950mm, 1150mm

|

|

Panel Weight

|

10-15kg/m2

|

|

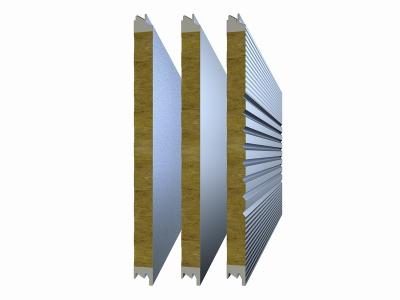

Sandwich

|

aluminum honeycomb, glass magnesium+Aluminum

honeycomb

|

|

Sound Transmission Loss

|

18db

|

|

Bending Resistance

|

1.0KN/m2

|

|

Fire Endurance

|

41min

|

|

Individuation

|

non-standard, wire tube, switch, opening reservation

|

|

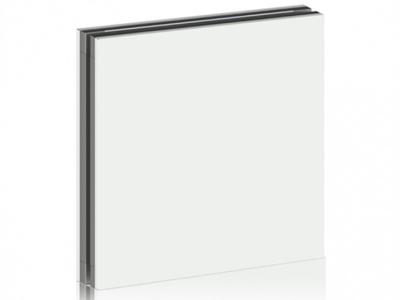

Applications

|

Metal Sandwich Panels for Hospitals Clean Rooms and

Pharmacy Clean Rrooms

|

2 Product Characteristics:

According to customer requirements, clean room technology can effectively control pollutants such as particles, harmful air and bacteria, and meet the requirements of precision, miniaturization, high purity, high quality and high reliability in product processing and experimental research. Optoelectronics, biomedicine, fine chemicals, aerospace, food processing and other industries have been widely used.

3 Product Production Machines:

The Cleanroon Production Line

The world's first automatic production line for clean board and non-standard flexible automatic production line is independently designed and developed by Wiskind and has complete intellectual property rights. Compared with the traditional manual production line, the automated production line improves the production efficiency by more than 6 times, and the precision, flatness and aesthetics of the clean board have been greatly improved, truly "making every clean board perfect."

As one of the top ten enterprises for National Metal Surface Envelope System and Modernized production base of construction industry in Shandong Province, we, WISKIND, has set up the production base in both Binzhou city and Yantai city, covering about 80, 000m2 land for modern-ized standard factory, and imported many advanced automatic production equipments, such as PUMA from Italy, RAS from Germany, ACL from USA. Furthermore, we also develop our own automatic production line for manual purification panel which is the first and only one in the world. Based on our professional skills, considerate service and reliable quality, WISKIND is looking forward to providing you innovative, reliable and economic solutions.

4 Product Project Cases:

--Product Project Cases of Yibang Bio

--Product Project Cases of Beijing Minhai Biotechnology Co., Ltd.

--Product Project Cases of Beijing Saisheng Pharmaceutical

English

English русский

русский español

español العربية

العربية 日本語

日本語 한국의

한국의 ไทย

ไทย Việt

Việt Indonesia

Indonesia українська

українська

online service

online service