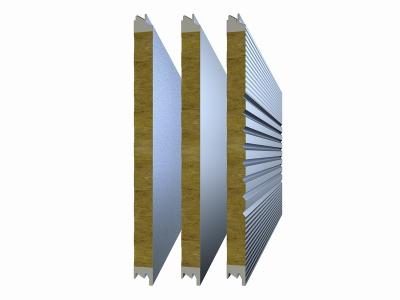

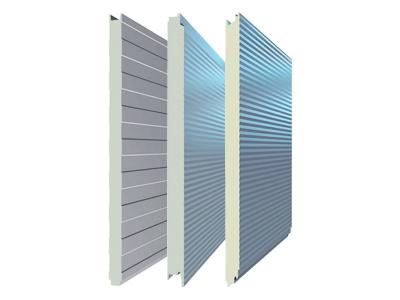

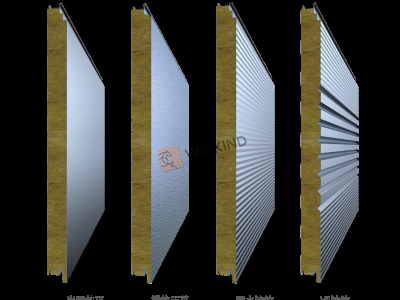

950mm Snap Cap Type Rock Wool Glass Wool Roof Sandwich Panel

Snap Cap Type Rock Wool Glass Wool Roof Sandwich Panel is bonded and pressed, trimmed, grooved, and blanked to form a tongue-and-groove composite board. Heat insulation, sound insulation, moisture resistance and other characteristics. Its plate's length is not limited, up to 12 meters or more, which fully meets the fire protection requirements of technical design. And it overcomes the defects that the previous sheet does not have sufficient integrity and rigidity, and has poor flexural and impact resistance properties.

English

English русский

русский español

español العربية

العربية 日本語

日本語 한국의

한국의 ไทย

ไทย Việt

Việt Indonesia

Indonesia українська

українська

online service

online service