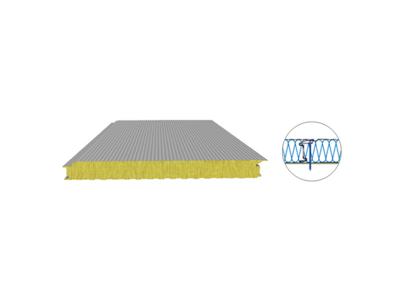

1 Product Parameters:

|

Items

|

Parameters

|

|

Effective width

|

1000 mm

|

|

thickness

|

50 mm / 75 mm / 100 mm...

|

|

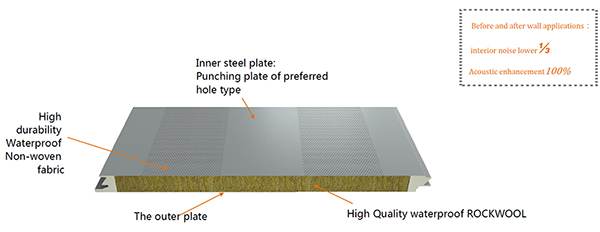

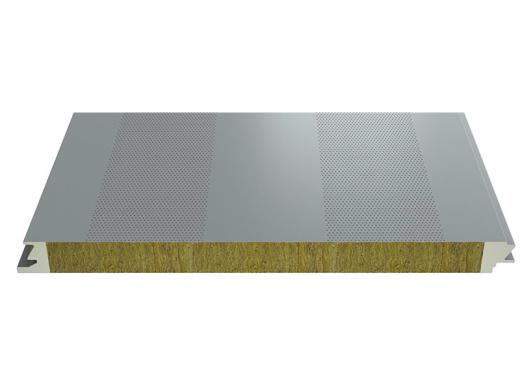

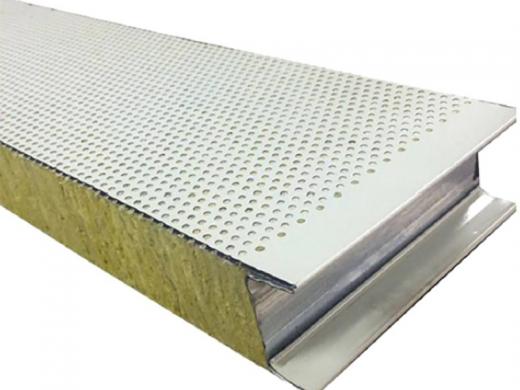

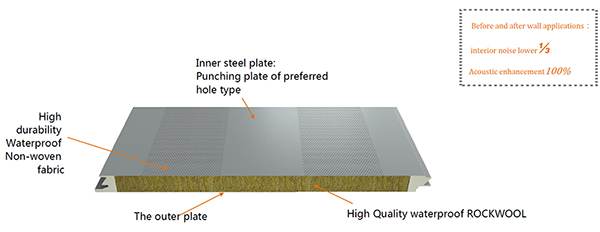

Inner steel plate

|

Preferably the punched color coated steel plate after the hole type, thickness 0.5~0.6 mm, flat rib (hole diameter 3mm, hole center spacing 5mm, hole arrangement 60°, open hole rate 32.7%)

|

|

Perforated plate face covering

|

Face protection material, high durability water-repellent non-woven fabric

|

|

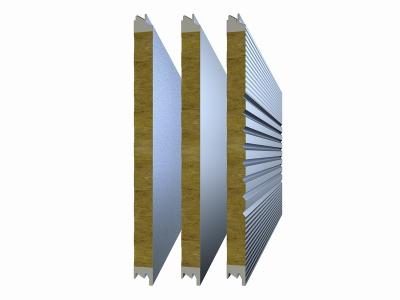

Core type

|

High quality hydrophobic rock wool, 100~120 kg/m3

|

|

Outer steel plate

|

High grade color coated steel plate, thickness 0.6-0.7 mm, Lishui ripple

|

|

Enterprise mouth form

|

Colorpod SD-0/SD-20

|

|

Fixed method

|

Hidden nail installation

|

|

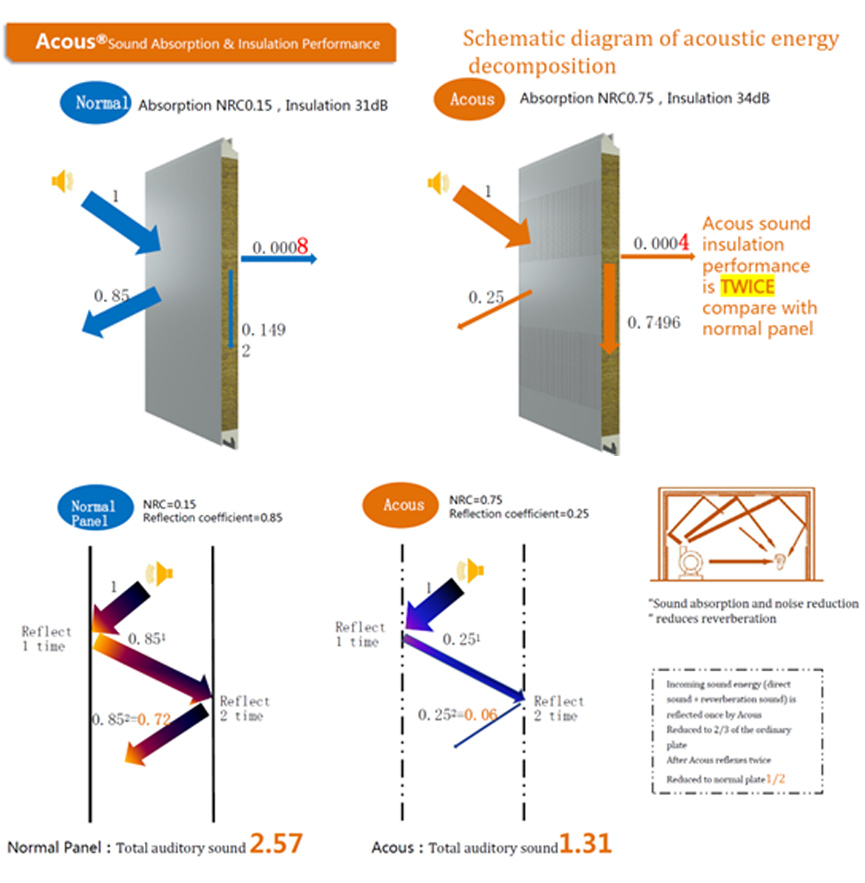

Sound absorption performance (50mm thickness)

|

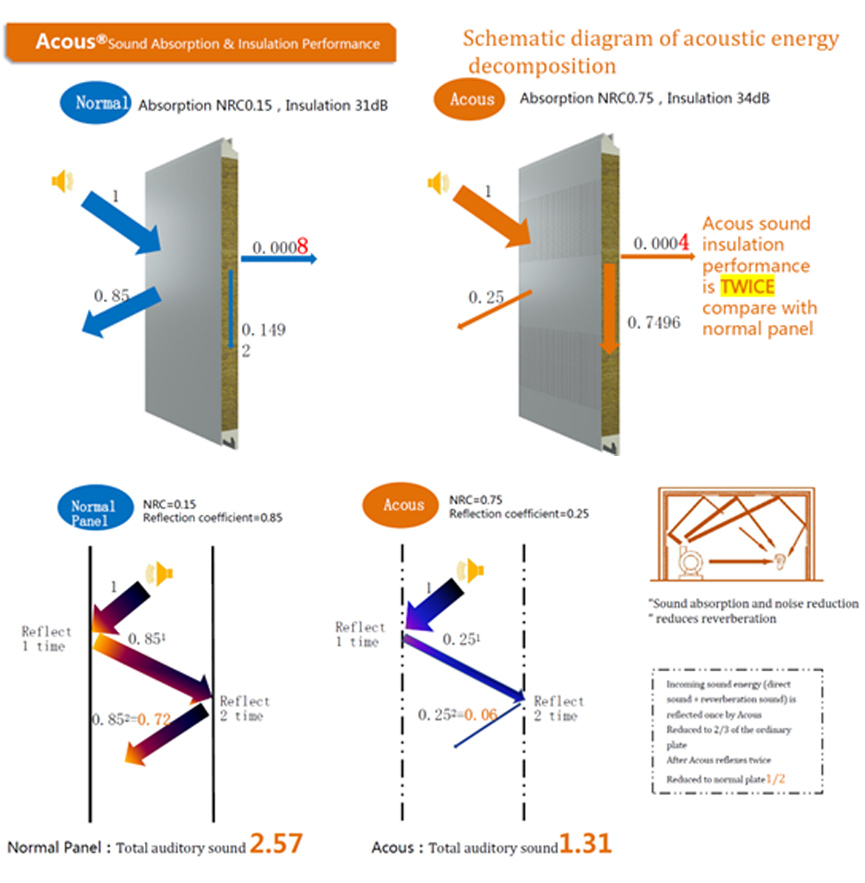

Noise reduction coefficient NRC= 0.75100~5000 Hz The average sound absorption coefficient is 0.64 For high-frequency industrial noise (3150~5000 Hz), the average sound absorption coefficient is 0.68

|

|

Sound insulation performance (50mm thick)

|

Weighted sound insulation Rw= 34 dB For high-frequency industrial noise (3150~5000 Hz), the amount of sound insulation is 40~50 dB

|

|

Mechanical properties

|

The bending load carrying capacity is comparable to that of ordinary sandwich panels

|

2 Product Characteristics:

|

Key innovation points

|

Basis

|

Key parameter design of CESAC sandwich panels

|

|

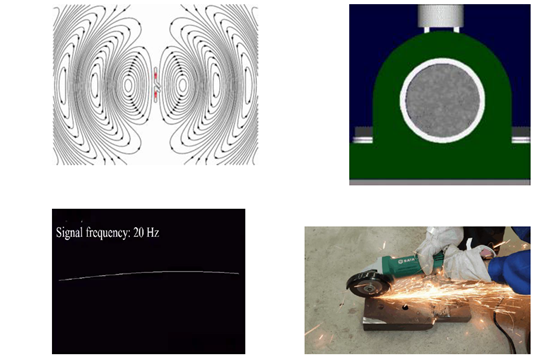

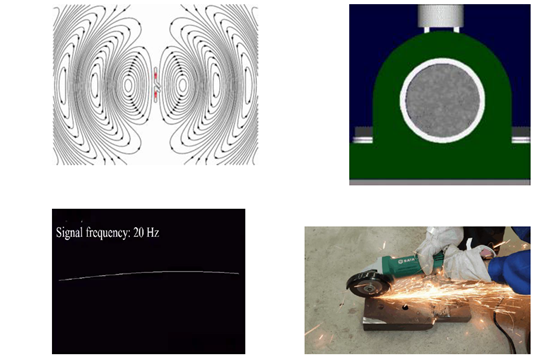

Noise spectrum analysis

|

Acoustic measurement of the acoustic properties of materials, human auditory system

|

Professional-grade acoustic spectrum analysis at 20Hz~20000Hz frequency acoustic test analysis

|

|

Hole type is preferred

|

The law between pore type and sound absorption

|

Select the pore type parameters and select the punching plate with good acoustic performance

|

|

Punching form

|

Low, medium and high frequency balanced absorption

|

Choose the way the punching bar is punched along the plate length direction to design the plate width of 1000 and the punching strip width of 250

|

|

Acoustic performance

|

Scientific testing by third-party authoritative institutions

|

The sound absorption and sound insulation performance are both excellent, reducing the noise sound pressure in the workshop by about 1/3, and significantly improving the occupational health level of the factory

|

|

Bonding process

|

Sound absorption principle and influencing factors of porous materials

|

Bond only in non-punched areas to meet the porous sound absorption rules

|

|

Core material selection

|

The sound absorption principle of porous materials and the influence of influencing factors on the sound absorption performance

|

The core material is "rock wool", not polyurethane and glass wool

|

|

Continuous production

|

Standardize production requirements

|

Enable continuous production

|

|

Mechanical properties

|

Meet the requirements of façade applications

|

The bending bearing capacity is basically the same as that of the non-punched plate to meet the requirements of the façade application

|

3 Product Qualifications:

4 Product Knowledges:

4.1 What it means from 62.4dB lower to 47.2dB ?

Industrial Noise→Convalescent environment

GB 3096-2008 Sound Environment Quality Standard—Table 1 Environmental Noise Limits Unit: dB(A)

|

Acoustic Environment ribbon category

|

Example of the Acoustic Environment ribbon

|

Daytime

|

|

Class 0

|

Rehabilitation areas, etc., especially quiet areas are needed

|

50

|

|

Class 1

|

Residential, cultural and educational areas that need to be kept quiet

|

55

|

|

Class 2

|

Commercial finance, market trade, etc., need to maintain a quiet area of residence

|

60

|

|

Class 3

|

Industrial production, etc., industrial noise

|

65

|

|

Class 4

|

4a: Highways, etc., traffic noise; 4b: Railway trunk lines, etc., traffic noise

|

70

|

4.2 The Noise hazard

1、Noise impairs hearing organs:Tinnitus, hearing deviation, noise deafness.

2、Noise causes a variety of diseases: central nervous system, cerebral cortex imbalance. Headaches, dizziness, insomnia and general fatigue. Still can make heart rate is accelerated, heart rate is irregular, blood pressure rises.

3、The influence of noise on normal life: studies show that 45dB noise begins to affect normal people's sleep. The noise near the factory is sometimes as high as 70~80dB, which will affect people's conversation, lectures and meetings.

4、Noise reduces labor productivity: in a noisy environment, people are irritable, easy to fatigue, and slow reaction. The effect of noise on precision processing or mental work is more obvious. When the noise of a switchboard is reduced from 50dB to 30dB, the error rate can be reduced by 42%. In addition, due to the psychological effect of noise, distracting people's attention, but also easy to cause industrial accidents.

• 0 -20dB:Silence, barely audible

• 20-40dB:Quiet and talk quietly

• 40-60dB:Average, average indoor speech

• 60-70dB:Loud, loud talk

• 70dB:The maximum noise that the EPA d etermines humans can tolerate (without hearing loss, sleep disturbances, anxiety , learning disabilities, etc.)

• 70-90dB:It's noisy and it damages n erve cells

• 90-120dB:Extremely loud, damage hearing

• 100-120dB:You go temporarily deaf in space in

• 120dB:The highest volume audible to the human ear

4.3 Industrial noise and classification

Industrial noise: refers to the noise generated by the operation of mechanical equipment, classified by sound source

1) Aerodynamic noise: produced by gas vibration. Gas turbulence caused by eddy currents in the gas, or sudden changes in pressure. Such as the noise generated by fans, blowers, air compressors, and high-pressure gas when they are vented.

2) Mechanical noise: produced by mechanical impact, friction and rotation. Such as noise from crushers, ball mills, chainsaws, machine tools, etc.

3) Electromagnetic noise: It is generated by the vibration of electrical components caused by magnetic field pulsation and power frequency pulsation. Such as the noise generated by generators, transformers, and relays.

English

English русский

русский español

español العربية

العربية 日本語

日本語 한국의

한국의 ไทย

ไทย Việt

Việt Indonesia

Indonesia українська

українська

online service

online service