1 Product Parameters:

|

Product

name

|

Pre-engineered

Structural Steel Workshop for Electronics Industry

|

|

Main

Structure

|

Weld H

steel/ Steel Beam/Column

|

|

Sub-Structure

|

C/Z

purlin,C/Z section steel

|

|

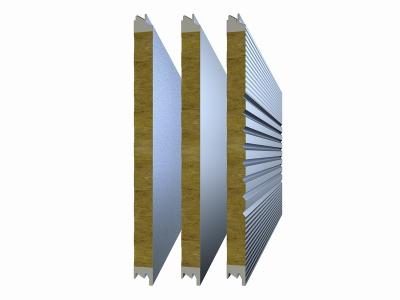

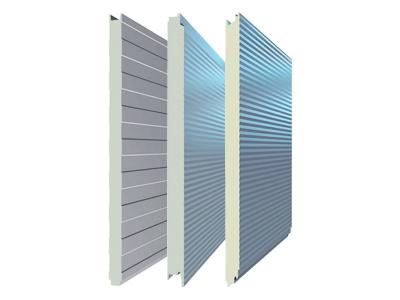

Roofing&Wall

|

Fireproof/Insulated

sandwich panels or corrugated steel plate

|

|

Connect

|

Hot-Wleded

|

|

Lighting

system

|

Lighting

panel/aluminum alloy window/sliding window/plastic steel window/aluminum

window with thermal insulation broken bridge

|

|

Ventilation

System

|

Stainless

Steel Ventilator

|

|

Walls/Roofs

|

Coated

Corrugated Steel Sheets/Steel Sandwich Panels/Clean Room Sandwich Panels

|

|

Certificate

|

CE/ISO9001/ISO14001

|

|

Application

|

Workshop/Warehouse/Storage/Frame/Shed/Any Steel Structure Buildings

|

2 Basic Knowledge Of Portal Light Steel Structure:

1. High strength and light weight. Compared with concrete, the strength of steel is much higher than that of concrete, so under the same force, steel structure has smaller components and lighter weight than concrete structure. Lower base costs.

2. Good material properties and high reliability. The steel is produced by the factory, with strict quality control, good material uniformity, and good plasticity and toughness, which is more in line with the ideal isotropic elastic-plastic material. Therefore, the currently adopted calculation theory can better reflect the actual working performance of the steel structure. , high reliability.

3. High degree of industrialization and short construction period. The steel components are all made in factories, and have the characteristics of mass production and high precision of finished products; the construction method of factory manufacturing and site installation can effectively shorten the construction period and create conditions for reducing the cost and giving full play to the economic benefits of investment.

4. Good seismic performance. Due to its light weight and relatively flexible structural system, the steel structure is less affected by earthquakes, and the steel has high tensile and compressive strength as well as good plasticity and toughness. Therefore, in the previous earthquakes at home and abroad, the steel structure has It is the structure with the lightest damage, and has been recognized as the most suitable structure for seismic fortification areas, especially strong earthquake areas. (According to the requirements of the portal frame specification: seismic check calculation is generally not required for seismic areas with degrees 7 and below);

5. Good heat resistance.

6. The price of steel is relatively expensive. After the steel structure is adopted, the structural cost will increase slightly, but the single factor of the structural cost should not be used as the main basis for deciding which material to use. If various factors are considered comprehensively, especially the advantages of the construction period, the steel structure will receive increasing attention.

7. Poor fire resistance. The fire resistance of steel structure is poor. In a fire, the unprotected steel structure can only last for about 20 minutes. Therefore, when fire prevention is required, fire prevention measures should be taken, such as clad concrete or other fireproof materials on the outside of the steel structure, or spray fireproof materials on the surface of the components.

Steel structure has been considered as a sustainable material, so from the perspective of long-term development, steel structure will have a good application and development prospect.

3 Envelope System Metal Raw Materials Of Different Paints:

|

class

|

peculiarity

|

limitations

|

Service life(General

Environment)

|

|

PE

(Polyurethane resin)

|

Good adhesion and easy to

process; The price is relatively low; High selectivity for color and gloss.

|

Not suitable for industrial

environments or heavily polluted areas

|

7 to 8 years

|

|

SMP

(Silicon modified polyester)

|

Higher weather resistance,

thermal stability and aging resistance, the price is more expensive than PE.

|

Not as good as PE in terms of

adhesion

|

10 to 12 years

|

|

HDP

(High-resistant polyester)

|

Strong anti-ultraviolet ability,

not easy to fade, powder.

|

|

15 years

|

|

HPC

(Self-cleaning polyester)

|

No softening occurs on the

surface of the steel plate, and dust molecules will not adhere or enter

In the coating, the hydrophilic performance is excellent.

|

It is not suitable for heavily

polluted heavy industrial areas and coastal areas with serious corrosion

|

15 years

|

|

PVDF

(Fluorocarbon resin)

|

Excellent weather resistance,

solvent resistance, corrosion resistance, wear resistance, UV resistance and

good processability and stain resistance, the price is higher. Note: Topcoats

use more than 70% Kynar®500 or Hylar®5000 fluorocarbon resin color plates for

best performance

|

Expensive

|

20 to 25 years

|

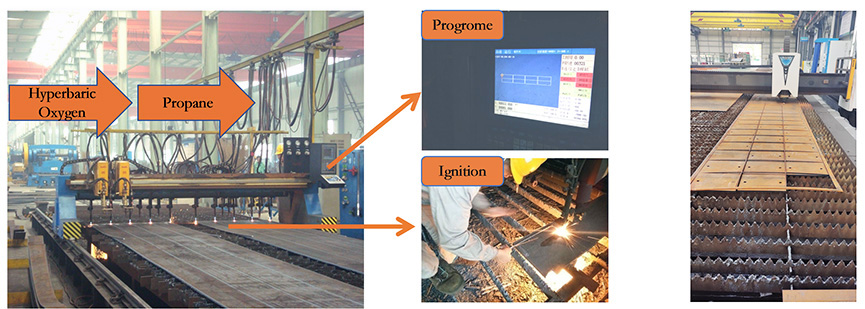

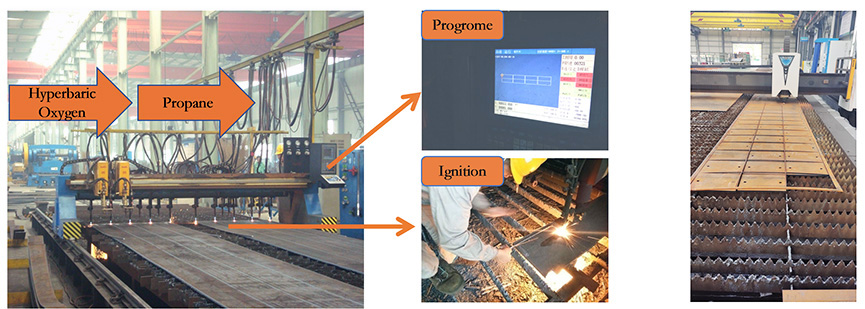

CNC cutting machine

CNC cutting machine is a commonly used cutting equipment, mainly cutting wing webs, column bottom plates, connecting plates and other special-shaped small parts, and a few processing plants use laser cutting or plasma cutting.

5 Electronics Industry Project Cases:

--Electronics Industry Project Cases Of Dehuai Semiconductor

--Electronics Industry Project Cases Of Kelton Electric

--Electronics Industry Project Cases Of Samsung Semiconductor

English

English русский

русский español

español العربية

العربية 日本語

日本語 한국의

한국의 ไทย

ไทย Việt

Việt Indonesia

Indonesia українська

українська

online service

online service